Do you know how to choose electrolytic capacitors?

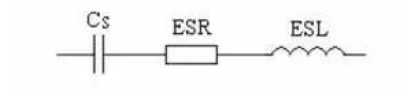

Electrolytic capacitors are one of the most important devices in primary and secondary loop filter circuits in switching power supplies. Generally, the equivalent circuit of an electrolytic capacitor can be considered as a series connection of an ideal capacitor with a parasitic inductance and an equivalent series resistance, as shown in FIG.

Figure 1 equivalent circuit of electrolytic capacitor

As is known, switching power supplies are the main power source for today's information appliances, making a great contribution to the small size and lightness of electronic devices. Switching power supplies continue to be smaller, lighter, and more efficient, and are increasingly used in electronic devices, and the penetration rate is increasing.

Capacity and volume

Since electrolytic capacitors are mostly wound structures, it is easy to expand the volume, so the capacitance per unit volume is very large, several times to several tens of times larger than other capacitors. However, the acquisition of large capacitance is at the expense of volume expansion. Modern switching power supplies require more and more efficient and smaller and smaller volumes. Therefore, it is necessary to find new solutions to obtain large capacitance and small size volume of capacitors.

Once an active filter circuit is used on the primary side of the switching power supply, the environment in which the aluminum electrolytic capacitor is used becomes more severe than before:

(1) The main switch of the inverter generates heat, which causes the ambient temperature of the aluminum electrolytic capacitor to rise;

(2) The high-frequency pulse current is mainly a pulsating current of 20 kHz to 100 kHz, and is greatly increased;

(3) The converter uses a booster circuit, so it is required to withstand high voltage aluminum electrolytic capacitors. As a result, the aluminum electrolytic capacitor manufactured by the prior art has to select a larger-sized capacitor because it absorbs a larger pulsating current than ever before. As a result, the power supply is bulky and difficult to use for miniaturized electronic equipment.

In order to solve these problems, it is necessary to research and develop a new type of electrolytic capacitor, which is small in size, high in voltage resistance, and allows a large amount of high-frequency pulse current to flow. In addition, this electrolytic capacitor operates in a high temperature environment and has a long working life.

Withstand temperature and life

In the switching power supply design process, it is inevitable to choose the applicable capacitor. For medium and large-capacity products of 100 μF or more, aluminum electrolytic capacitors are the most widely used because they are inexpensive. However, significant changes have occurred in recent years, and situation of avoiding using of aluminum electrolytic capacitors is increasing.

One reason for this change is that the life of aluminum electrolytic capacitors tends to be a weak link in the entire device. The engineer of the power module manufacturer said: "For aluminum electrolytic capacitors, such a component with limited life, if it is not necessary, try not to use it." Because the electrolyte inside the aluminum electrolytic capacitor will evaporate or cause chemical changes, resulting in a decrease in electrostatic capacity or The equivalent series resistance (ESR) increases, and the performance of the capacitor will definitely deteriorate over time.

The life of an electrolytic capacitor is directly related to the ambient temperature at which the capacitor is operated for a long period of time. The higher the temperature, the shorter the life of the capacitor. Ordinary electrolytic capacitors have been damaged at an ambient temperature of 90 °C. However, there are many types of electrolytic capacitors that have a high operating temperature. When the ambient temperature is 90 ° C, the ratio of the alternating current to the rated pulse current through the electrolytic capacitor is 0.5, the lifetime is still 10000 h, but if the temperature rises to At 95 ° C, the electrolytic capacitor is damaged.

Therefore, when selecting a capacitor, it should be selected according to the specific ambient temperature and other parameter indicators. If the influence of the ambient temperature on the life of the capacitor is neglected, the reliability and stability of the power supply operation will be greatly reduced, and even the equipment will be