How is capacitive sensing applied in video games?

The speed of drawing and processing can limit or show the development of software in the game, so it is most likely to get the attention of consumers and critics. The console controller is also very important. The interface method of the video game controller is constantly being developed, in order to be able to interact more effectively with the scene displayed on the screen.

Although most video game development focuses on software and processors, many of the major creative and forward-thinking ideas are related to controllers. As game system and peripheral manufacturers strive to improve the way players interact with their systems, they are constantly developing and improving in terms of ergonomics, style, functionality, or features.

Finding New Paradigms

We may all remember the earliest Atari controllers with a square base, with a joystick in the center and a button next to it. It was quite enough for video games at the time. Because all that was needed at the time was a basic directional control and a selection button, the game could be played, and this controller was exactly what was needed. Nintendo later released the Nintendo Entertainment System, a quad controller, in which the direction button replaced the joystick and a second button was added, which is a major change based on existing technology.

Since then, controllers have become more complex. There are now more buttons on the standard console controller than ever before, and each button has more powerful features. The pressure-sensitive discontinuous button allows better control of its triggering effect, especially for braking and acceleration control in driving video games.

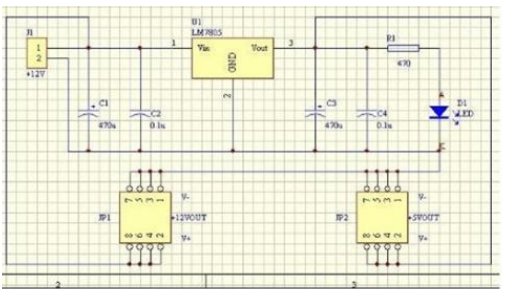

And the key combination in the fighting game is also a capacitor-to-voltage converter using switched capacitor technology. The vibration function (rumble-packs) allows players to experience the real feeling, instead of just sound and light effects. Thanks to the superior analog functionality of the joystick, it is revived on the latest controllers. Capacitive sensing technology (capacitive touch sensing) is the latest interface technology that can improve the usability of game controllers and the most stunning mechanical design.

Overview of Capacitive Sensing Technology

Capacitive sensing is most commonly used on personal computer touchpads and portable media players. Mobile phone manufacturers have also begun to invest in promoting their use, and have developed several models for sale. The simple structure, device water resistance, and rugged mechanical design are all attractive features of the capacitive sensing interface.

method

There are several ways to achieve capacitive sensing, but the basic elements are fixed. Among them, the capacitive sensor is only a copper pad connected to the controller circuit in a printed circuit board. The combination of the sensing button and its connecting wire creates capacitance around it.

The ground plane, metal support, and other electronic and mechanical components considered in the design all affect the capacitance of the sensor. It is generally considered that the capacitance of a sensor is equivalent to the capacitance between it and the ground plane. When a conductive triggering substance (such as a finger) approaches the sensor to a certain extent, the capacitance value increases. This is because the conductor itself will create more possible paths between the sensor and the ground plane, and more paths will generate more field lines, which will increase the overall capacitance value.

The front end of the capacitive sensor is composed of switched capacitors, an internal current source, or a voltage source with an external resistor. These methods are all to input the voltage value on the sense capacitor. The voltage value can be processed by an ADC or a charging time measurement circuit formed by a comparator, and then reaches a counter or a timer. When the digital output value is used by the data processing and decision-making of the capacitive sensing system, it will cause a transition in the ADC output value or an analog transition in the count value in the capacitive mass. Later we will discuss the two commonly used methods, namely relaxation oscillator (oscillaTIon) and continuous approximation method (successive approximaTIon).

Actual design

It is not difficult to build a capacitive sensor in the actual design. As mentioned above, a capacitive sensor is nothing more than a conductive piece, usually a copper piece, placed on a printed circuit board. And this conductive piece is not only directly connected to the control component through the triggering substance, usually a finger, but also directly interacts with it. The sensor board is placed on an overlay surface directly below the sensing area. It is best not to have any air between the sensor and the cover, and the sensor substrate should be tightly adhered to the cover with a non-conductive adhesive.

The control circuit can be placed near the sensor, and the closer the better. The mechanical requirements of the sensor determine the configuration of the control circuit. The longer the distance between the sensor and the control circuit, the original capacitance value between the sensor and the ground plane will increase accordingly, because the wire will interact with the surrounding environment, and then increase the capacitance value; the longer the distance, the more obvious the increase.

Although it is not easy to specify the maximum distance, in general, 6 to 12 inches can be considered a functional limit. The substrate for capacitive sensing applications is not fixed; the most common design is a basic FR4 printed circuit board with copper wires. In addition, flexible printed circuit boards with copper sheets (usually polyimide film-Kapton) are also common. Flexible substrates make mechanical design easier, especially on curved surfaces. The conductive ink printed on an elastic substance such as carbon or silver can make a capacitive sensor at a very low cost, but because the elastic substance cannot be soldered, it is necessary to control the printed circuit board and the connector.

Transparent conductive materials, such as indium tin oxide (Indium TInOxide; ITO), are also rapidly being widely used in touch screen applications. The ITO sensor is printed on glass or polyethylene terephthalate (PET) film, and then combined with the final design. Although chip-on-glass is currently used to control such applications, it is more economical to use flexible connectors or hot bar soldering on printed circuit boards.

If you want to know more, our website has product specifications for sensor, you can go to ALLICDATA ELECTRONICS LIMITED to get more information