What is the principle of electromagnetic emission and magnetic field interference?

Electronic and electrical products radiate electromagnetic disturbance to the surrounding space at the same time. The radiated disturbance field strength often exceeds the limit in certain frequency bands, which will affect the normal operation of the surrounding electronic equipment and itself. Therefore, it is important to understand the cause of exceeding the standards and the suppression methods of electromagnetic emission and magnetic field interference for the product's electromagnetic compatibility (EMC) design.

Generation mechanism of electromagnetic emission and magnetic field interference

1) Electromagnetic emission

During the operation of various digital circuit chips and high-frequency analog circuit chips, antenna effects are generated due to unreasonable design of PCB traces or the connection of various parts of the product, and radio frequency interference caused by electromagnetic waves is emitted. When the electromagnetic wave energy reaches a certain value, it will affect the normal operation of surrounding electronic equipment and itself.

2) Magnetic field interference

The magnetic field generated during the operation of the power line and the high-frequency inductive components inside the product interferes with the product operation through radiation, causing work disorder.

In electronic products, the frequency of the signal transition edge of digital circuit chip ports can reach hundreds of megahertz, and some analog circuit signal frequencies reach more than megahertz. These digital or analog signals may conduct interference through wires or radiate to the air, affecting The electronic device itself and interferes with other electronic devices. The basic measures for suppressing electromagnetic emission are as follows.

2.1 Reduce the energy of interfering signals

1) On the premise of not affecting the overall performance of the product, reduce the transition rate of the digital signal or reduce the transmission speed of the digital signal;

2) The use of chip components shortens the external pins of the high-frequency working chip and reduces the length of the high-frequency signal transmission line, which can suppress the antenna effect and reduce the high-frequency signal radiation energy.

2.2 Isolating the propagation path of interference signals

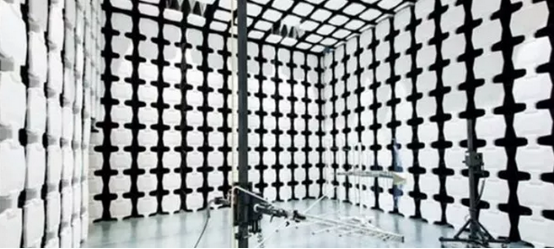

Grounding in electronic equipment is one of the important methods to suppress electromagnetic noise and prevent electromagnetic interference. The simplest and most effective isolation method is shielding, also known as "shield grounding", which refers to the grounding of the shielding layer (body) used to suppress interference in order to play a good role in anti-interference. There are three common methods of shielding:

1) Encapsulated with magnetically permeable metal material shell, the shell is reliably grounded (earth ground);

2) Local circuits or IC chips that are prone to high frequency radiation plus a metal shield, and the shield is connected to the signal ground;

3) Copper on both sides of the circuit board that transmits high-speed digital signals or high-frequency analog signals is connected with signal ground to achieve isolation from other signal lines.

2.3 Filtering

The filter can suppress both conducted interference from electronic equipment and conducted interference from the power grid. EMI (electromagnetic interference) filters are mainly used to suppress interference. The EMI filter consists of a linear component circuit and is installed between the power line and the electronic equipment. It can pass the power frequency and prevent high-frequency noise from passing, which plays an important role in improving the reliability of the equipment.

1) Connect decoupling capacitors or decoupling resistor capacitors directly between the power pins of the circuit chip to filter out high-frequency interference signals that enter the chip through the power supply traces;

2) Set a power filter at the AC 220 V power input end of the product to prevent high-frequency interference generated by the product from entering the power grid.

3. Interference mechanism of electromagnetic energy and its suppression source

When electric current flows in high-frequency wires (or copper bars) in electronic products, the magnetic field generated around the wires; the leakage magnetic flux that high-frequency transformers and all inductive components of switching power supplies must produce during operation. The above magnetic flux passes through the chip or the sensitive circuit module. The charged particles (electrons and holes) in the semiconductor are subjected to Lorentz force in the magnetic field and deviate from the original direction of movement, so that the working current waveform of the chip and the module is modulated by the magnetic field change Distortion occurs, causing the normal operation of these chips or circuit modules to be disturbed. The signal current always flows in a closed loop. When the external disturbance magnetic flux passes through the area enclosed by the closed loop, a current will be induced in the closed loop, and the current waveform will also be distorted. The basic measures to suppress electromagnetic energy interference are as follows.

3.1 Shielding interference magnetic field method

The most commonly used measure to suppress magnetic field radiation interference is to use conductive or magnetically conductive materials for shielding.

1) When the changing interfering magnetic flux passes through a conductive material (such as a thin copper skin), eddy currents will be generated therein and a magnetic flux in the opposite direction will be generated, which can weaken the interfering magnetic flux passing through the conductive shielding layer;

2) The high-frequency transformer magnetic core is covered with a thin copper skin forming a short-circuit ring, which can effectively suppress the leakage of magnetic flux leakage from the transformer;

3) Using magnetically permeable material (iron plate or steel plate) as the chassis of the device is a common method for magnetic shielding of the whole machine. This method can not only prevent external magnetic flux from entering the electronic device, but also prevent internal magnetic flux from leaking out. The better the magnetic permeability of the shielding material, the thicker the board, the less likely that the chassis will be magnetically saturated, and the better the shielding effect.

3.2 Reduce the loop area of the signal current

The purpose of reducing the area of the signal current loop is to reduce the interfering magnetic flux that passes through it. Common measures:

1) Twisted pair cable is used to make the outgoing and return wires of the signal current tightly twisted, which can reduce the area surrounded by the return;

2) Use shielded wires for externally introduced signal wires. When using the core wire as the signal current to go, the copper wire braided shield layer as the signal current return line, must be single-terminated to the signal ground. The loop area of this method is smaller than the twisted pair, and the shielding layer can also achieve magnetic field shielding;

3) On the premise of ensuring insulation safety, the signal line and ground line in the PCB are as close as possible to reduce the area surrounded by the signal current loop;

4) When selecting the IC chip and circuit module on the PCB, under the condition of ensuring the circuit function, the package with the power supply lead pin and the zero volt line pin as close as possible should be selected as much as possible;

5) When designing the PCB, ensure that the power supply line and the zero-volt line are arranged close to each other while ensuring the insulation safety.

If you want to know more, our website has product specifications for the electromagnetic emission and magnetic field, you can go to ALLICDATA ELECTRONICS LIMITED to get more information