What is the patch connector in the wire-to-board connector?

Connectors are everywhere in life, and we are no strangers to connectors. In the previous article, the editor has done many explanations on the connector. In this article, we will explain the patch connector in the wire-to-board connector, and introduce the advantages of using 3d printing technology to manufacture the connector. If you are interested in the content of this article, you may wish to continue reading.

1. Introduction of SMD connectors in wire-to-board connectors

There are many types of connectors, which can be divided into round connectors, rectangular connectors, square connectors, customized connectors, etc. according to their appearance. According to the contact body termination form: crimping, welding, winding; screw (cap) fixation; according to the connection method can be divided into: board to board connector (B to B), wire to board connector (W to B), Wire-to-wire connectors (W to W).

Surface mount technology has been used by some manufacturers since the 1950s. However, the use of SMD connectors has only recently begun and is gradually being valued by manufacturers. This situation arises from the technical difficulties faced by SMT connectors and the failure to perceive that patch connectors can effectively save board area. As people find that the SMD process can improve the production efficiency and reduce costs for manufacturers, it can also reduce the board area and improve the design flexibility, which makes the SMD connector widely used.

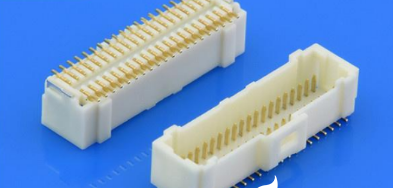

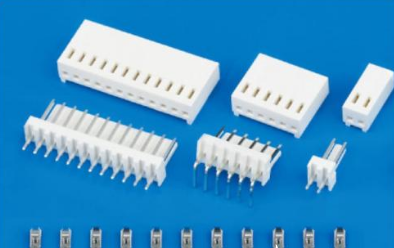

SMD connectors are divided into: lying connector (SMT) and standing connector (DIP). SMT generally mounts lead-less or short-lead surface-mounted components. It is necessary to print solder paste on the circuit board, then mount it through the placement machine, and then fix the device by reflow soldering. The DIP welding is a device in the form of a direct insertion, and the device is fixed by wave soldering or manual welding. The temperature of the patch connector is over 260 ° for 3-5s. The composition of the patch connector: plastic parts and pin pins, the material of the plastic parts is generally PA6T and PA9T, which are high temperature resistant materials. SMD connectors are generally used in various fields such as highway cameras, stereo DC fans, smart electronics, air conditioners, high-definition LCD TVs, notebook computers and so on. The material of Pin is generally brass, bronze, phosphor bronze, etc. The plating layer is generally gold-plated (half-gold) or tin-plated. The coating function of the Pin is to resist oxidation, improve the conductivity, and increase the signal transmission speed. Second, the advantages of using 3d printing technology to manufacture connectors Nanofabrica's additive manufacturing (3D printer technology) platform may be the first cost-effective and repeatable micron-resolution AM technology that can achieve micron resolution on centimeter-sized parts and can be in a single configuration Manufacture thousands of parts and components. One area where this technology fits perfectly is the manufacture of various micro-optical parts and components. This ability to produce complex, extremely flat, extremely small, and extremely lightweight optical components has opened up potential for product innovation in many industrial fields. In addition, for various reasons, including green manufacturing considerations and design freedom to work in plastic, because plastic has become an increasingly popular material for micro-optical applications. Cylindrical microlens, 20 microns high and 100 microns wide. The surface roughness is about 1 micron, and the material has 80% transparency to visible light.

In fact, micro-injection molding has already become a popular technology in micro-optics manufacturing, but it wasn't until the introduction of Nanofabrica's AM technology that it truly became the only viable technology for low-cost, mass-production. Using injection molding for micro-optic manufacturing requires optimized design, tools, and production steps, which means close interaction between suppliers and product developers is crucial. Nanofabrica's technology overcomes the complexity problem, the key is to eliminate the need for tools, so the technology can be used in a series of applications, such as the manufacture of optical alignment fixtures and fixtures, optical connectors for optical fibers, optical fibers Ferrules and other small related components, as well as optical components such as lenses and prisms.

If you want to know more, our website has product specifications for connector, you can go to ALLICDATA ELECTRONICS LIMITED to get more information