How about xMEMS releasing the world's first monolithic MEMS speaker?

Speakers are not part of our traditional report, but the new speaker technology announced by xMEMS today is something everyone should pay attention to. The voice coil speaker we know has existed in one form or another for more than one hundred years, and it is the basis for our experience of audio playback. In the past few years, semiconductor manufacturing has become more common and accessible, and MEMS (Micro Electro Mechanical System) technology has now developed so that we can design speakers with fundamentally different characteristics from traditional dynamic drivers or balanced armature units.

xMEMS is a newly established company, established in 2017, headquartered in Santa Clara, California, with a branch in Taiwan. So far, the company has been in stealth mode and has not released any products publicly until today. It is reported that the company’s motive is to use the founder’s rich experience accumulated in different MEMS design companies over the years to break through decades of speaker technology barriers and reshape the sound with brand-new innovative pure silicon solutions.

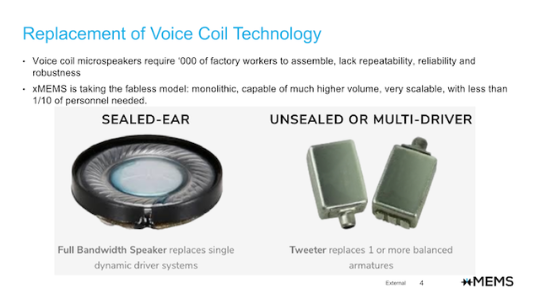

The manufacture of xMEMS pure silicon speakers is very different from the manufacture of traditional speakers. The speaker is essentially just a monolithic piece, manufactured through a typical photolithography manufacturing process, just like other silicon chip designs. Due to this monolithic design, the complexity of the production line is greatly reduced compared with the voice coil design, because the voice coil design requires a large number of precision assembly and thousands of factory workers.

The company does not want to disclose the actual process node of the design, but they only confirmed that this is a 200mm wafer technology. In addition to the simplification of the manufacturing line, another major advantage of MEMS speaker lithography is that its manufacturing accuracy and repeatability are significantly better than those of voice coil designs with large changes. The mechanical design also has key advantages, such as higher membrane movement consistency, which can achieve higher responsiveness and lower THD active noise reduction.

The Montara design of xMEMS uses an 8.4 x 6.06 mm silicon mold (50.9 mm) with 6 so-called speaker “units”, that is, a single speaker MEMS element that repeats on the entire chip. The frequency response of the loudspeaker covers the entire range from 10Hz to 20KHz. This is a problem with current dynamic drivers or balanced armature drivers. This is why we see the use of multiple such loudspeakers to cover different parts of the frequency range.

It is said that this design has excellent distortion characteristics, comparable to planar magnetic designs, and promises only 0.5% THD in the 200Hz-20KHz range. Because these speakers are capacitive piezoelectric drives rather than current drives, they can reduce power consumption to a fraction of a typical voice coil driver, using only 42W of power.

Size is also a key advantage of the new technology. At present, xMEMS is producing a standard package solution. The sound is transmitted vertically from the package. Its footprint is the above-mentioned 8.4×6.05×0.985mm, but we will also see a side-emitting solution, which has the same The size, however, allows manufacturers to better manage internal headset design and component positioning.

This article is from Allicdata Electronics Limited which offer electronic components, semiconductors, antennas, capacitors, connectors, diodes, transistors, IC,resistors. For more product information, please go to the website to get it.