Thermal management in displays is not just heating components

Structures in the display (such as control electronics or components) emit different amounts of heat, even in small ranges. This makes certain areas, such as around the chiplets, warmer or cooler. If it is overheated in some places, the entire display may be damaged.

Thermal management is more than just overheating a processor or component. Even if it is cold, it will not close this topic. Instead, it is about how to balance the temperature or produce the right temperature in all production processes.

Thermal management has been and will remain one of the most important topics related to displays and embedded systems. If thermal management does not work, various indirect damages can occur. Of course, direct mechanical and electrical failures can occur due to excessive stress on the materials and components.

The problem is that with smaller and smaller profits, more and more vendors are moving toward integrated solutions and optimal packaging ready displays, embedded PCs or controllers that include a compact chassis to power as much as possible.

The results on the surface are usually general overheating and hot spots, but these are rarely alone. Because: not only the display is a heater, but also all electrical components, associated power supplies and processors, as well as often forgotten ambient temperatures, including sunlight, can cause temperatures to rise.

In addition, the internal water heater and the sun are unable to get rid of excess heat to mate outdoors, providing the extra energy needed for preheating. If a thermal problem is detected, the method of repairing it is usually superficial and rarely really adapts to the application. Therefore, first select one or more fans or heat sinks, even if you use speed control. But in most cases these methods are pure speculation or simply ignored.

Therefore, the desire for a one-size-fits-all solution has become overwhelming. Of course, this may not cost anything. Since part of the ownership consideration for total cost is actually very fast, a real function and adapting to different applications and installations increases thermal management costs, and where appropriate, the device concept is a bit more. However, this has been compensated several times in terms of reliability and MTBF, and several times significantly reduced downtime.

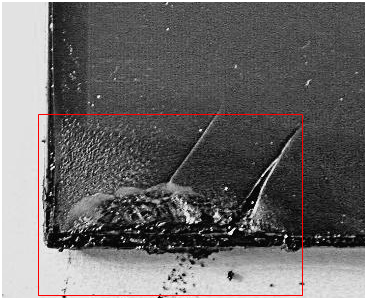

Excessive heat burned the display. You can see the ash in the red box in the lower left corner. The integrated design didn't work, so Edge Light first burned the entire display.

If dust and moisture have penetrated the hermetic seal of the embedded system, it can react in a closed space.

The real importance of thermal management

In terms of total cost of ownership, the technically best or most mature solution is the most commercially viable solution. Unfortunately, this way of thinking is less and less, because every value creation aspect is now an independent, cost-optimized entity. Most importantly, this usually does not focus on the subsequent stages of value creation - and therefore does not affect the actual operation. After all, this preventive thinking is rarely paid.

Only things that are paid on paper can be paid off. However, there are more and more comparable key figures that are one-to-one, and preferably also linearly comparable or at least comparable. Unfortunately, these simple key people don't exist. It is not a "one size fits all" motto at all, and certainly not with the ever-increasing technical complexity, it is inevitable to go hand in hand with each new generation of equipment.

Therefore, good and practical thermal management includes not only the total waste heat of all components in the system. In addition, it is impossible to provide such waste heat completely in principle.

Case study cold spot

In order to prevent overheating, whether large or small, the person in charge must rely on knowledge, know-how and preventive measures, as well as medical advice, sports, investigations and analysis of previous cases.

Moisture can also cause many unrecognized injuries at first glance. Damage does not occur immediately compared to overheated display units. For example, in the case of humidity, temperature differences can also have an effect: not only do hot spots with significant thermal problems, but also cold spots that form condensate. When the temperature increment reaches a certain level, depending on humidity, air pressure and pollution, condensation occurs in the unit or in the embedded system, causing some lines to be damaged, short-circuited or producing parasitic inductance or capacitance.

The desiccant in the outer casing is not a panacea because the material actually collects water , if it exceeds the water holding capacity at some point, it further speeds up the damage. Short circuits are a common problem due to the conductivity of aqueous solutions. In addition: water is also chemically active due to the substances dissolved therein. Therefore it may become alkaline or acidic and not only cause corrosion to electronic components. Since water is always trying to spread, damage can also occur in places that are difficult to see.