What are the welding materials and the selection of solder?

A solder material is a fusible metal or metal alloy used to join a metal to be soldered during soldering. Its melting point is lower than that of the metal to be welded, and it is easy to form an alloy with the surface of the metal to be welded.

1. Classification of solder

The solder material is classified into Sn-Pb solder, silver solder, copper solder, etc. According to its composition.

The solder is divided into wafer solder, Pb solder, ball solder, solder, and the like according to its shape. The solder is classified into a high temperature solder and a low temperature solder according to the temperature of the use environment.

The requirements for solder are low melting point, wide application range, fast solidification, good wetting effect, easy formation of solder joints, strong corrosion resistance, and can adapt to various harsh environments such as high temperature, low temperature, humidity, salt spray, etc. The price is cheap, which is conducive to reducing manufacturing costs.

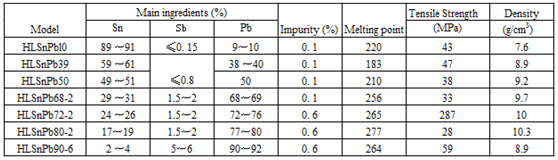

In the soldering of electronic products, Sn-Pb series solder, commonly known as solder, is commonly used. It is composed of two or more kinds of metal materials in different proportions. The composition and proportion of the alloy in the solder have a great influence on the melting point, density, mechanical properties, thermal conductivity and electrical conductivity of the solder. The common solders on the market vary greatly in composition and ratio. In order to meet the needs of welding, it is very important to choose the appropriate solder. The common types and proportions of solders and their properties are shown in Table 1. The soldering type is expressed by the element symbol “SnPb” of Sn and Pb, plus the element content. The percentage (usually the percentage of Pb) is composed, for example, SnPb 68 represents 32% Sn and Pb is 68% Sn-Pb solder.

Table 1

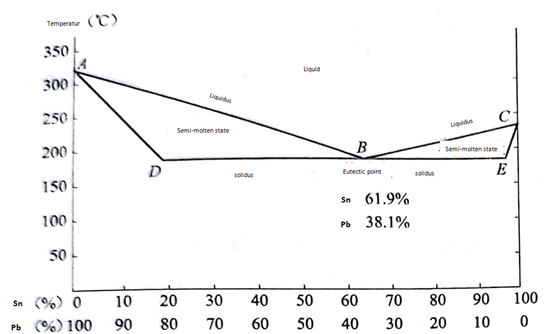

The state of the Sn-Pb alloy solder is related to the content of the Sn-Pb component. As shown in Figure 2, the state diagram of the Sn-Pb alloy shows the ratio of the Sn-Pb ratio and the relationship between the heating temperature and the state of the alloy.

As can be seen from the line in Figure 1, point A (pure lead), point B (eutectic point, Sn 61.9%, lead 38.15%), point C (pure Sn) three points, liquid and solid conversion is at a single temperature Under the other alloys, the change of state is carried out in a temperature range. Within this range, the state of matter is triggered by a semi-fusion. Above the ABC curve, the alloy is in a liquid state. This curve is called the liquidus. Below the ADE curve, the alloy is solid. This curve is called the solidus line. The liquidus and solidus intersect at point B, point B. Known as the eutectic point, the Sn-lead alloy prepared according to the ratio of the eutectic point is called the eutectic alloy. The melting point of the common alloy is 183C, the heating temperature reaches 183C, and the eutectic alloy changes from solid to liquid. Improve the quality of welding, is the most ideal solder.

Figure 1

2. Selection of solder

According to the properties of the metal material to be welded and the welding requirements for temperature, mechanical strength and other factors, select the appropriate solder. For hand soldered printed circuit boards and components whose soldering temperature is not too high, solders with low melting point, short solidification time and high strength should be used.

For welding wires, galvanized iron sheets, lead pipes, etc., solder with a higher lead content should be used. Although the melting point is high, it will not cause damage to the workpiece, and its cost is low.

Wave soldering and dip soldering should use eutectic solder.

If you want to know more, our website has product specifications for the solder, you can go toALLICDATA ELECTRONICS LIMITED to get more information.