What are the applications of ultrasonic sensors?

Using high-frequency sound waves to detect the position and distance of objects, ultrasonic sensors can usually work when other types of sensors are insufficient. They work like echolocation in bats or dolphins. These sensors emit sound waves (not heard by humans) and then detect when the sound waves bounce after hitting an object. By using sound, ultrasonic sensors can detect objects that frustrate other types of sensors, and can work in some very clever situations.

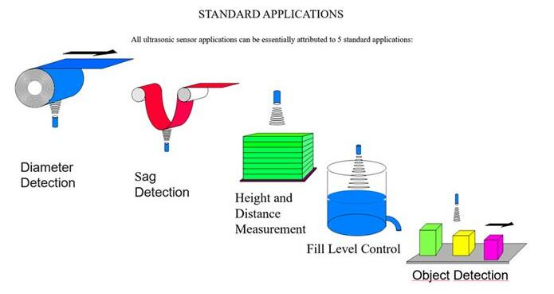

The following are five examples of ultrasonic sensor applications.

Assist in the detection of ultrasonic targets in driving. Many major automakers and technology companies are testing fully autonomous self-driving cars. Nissan and General Motors even stated that by 2020, they will test-run autonomous vehicles on the road. Both autonomous vehicles (and human-driving cars that incorporate driver assistance technology) extensively use sensors to monitor the road and surroundings. surroundings. For example, ultrasonic sensors can detect cars in adjacent lanes for "blind spot detection" and alert the driver when someone is in the blind spot.

Ultrasonic distance detection. Similarly, ultrasonic sensors can also prevent collisions by detecting when cars or other objects in front of and behind the car are approaching dangerously. For example, when parking, the sensor can monitor the distance between the car and the wall or other vehicles and remind you to park. The same applies to traffic conditions, because these sensors can work even if two objects are in motion.

Ultrasonic diameter detection. Ultrasonic sensors enter the factory away from the road and can help keep the automated production line running smoothly. Using printing facilities, such as those that print newspaper or magazine pages, the paper usually starts with a roll, and as the paper is used, the diameter of the roll decreases. Using ultrasonic sensors, the device can automatically detect when the reel is used up, so they can prepare to replace it with a new reel without losing productivity. Ultrasonic sensors can even be used with sound-absorbing materials, such as rubber or fillers.

Ultrasonic dent detection. Ultrasonic sensors can also ensure that any conveyor belts, wires or cables that may be used in manufacturing or other industrial environments are placed where they should be. Sagging cables will slow down or stop the production line. These sensors can automatically detect whether these objects are running evenly and even need to be tightened. Ultrasonic sensors can perform with incredible accuracy, which means they can even detect tiny defects or malfunctions. Even better, particles such as dust that may be produced during the manufacturing process will not affect its sensing ability.

Ultrasonic liquid level detection. This is another example of process automation in the food production industry. The ultrasonic sensor adopts hygienic design and is completely encapsulated in stainless steel, which can maintain good performance even when handling food. For example, it can help dairy factories produce cheese continuously rather than batches by monitoring the levels of milk and rennet in the coagulator. This way, it knows when to provide more of these ingredients when the cheese curd is continuously removed at the other end.

This article is from Allicdata Electronics Limited which offer electronic components, semiconductors, antennas, capacitors, connectors, diodes, transistors, IC,resistors. For more product information, please go to the website to get it.