What is the application principle of open-ended Hall current sensors in power distribution systems?

DC power distribution system usually consists of high-frequency switching power supply and battery. It is used to provide reliable DC power for control, signal, relay protection and automatic devices, accident lighting, etc. There are high requirements for power quality. Therefore, it is very urgent to make corresponding modification to some long-service DC systems. In addition, there is no power failure during the DC system transformation, and the engineering transformation is difficult. Traditional closed-hole Hall current sensors or shunts cannot be used. Therefore, open-ended Hall current sensors can be used to solve the problem of DC current measurement in the transformation project and ensure the transformation process. No power outage and safe operation.

1 Product design

1.1 Structural Features

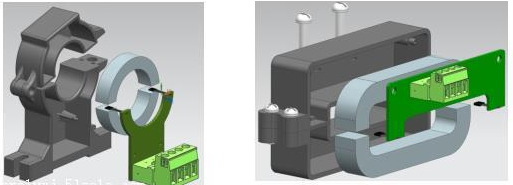

Open-type Hall current sensors are developed on the basis of traditional closed-hole Hall current sensors, with novel structure and beautiful appearance. The whole is composed of shell, iron core, sampling circuit board and fixed resin. The shell material is made of PC / ABS alloy, which has the characteristics of high temperature resistance, high mechanical strength and environmental protection. The iron core uses oriented cold rolled silicon steel sheet, which has stable performance and mechanical properties. High strength, extremely high magnetic permeability, etc .; green pluggable terminals are used for circuit boards and external wiring, making field wiring convenient and reliable. The specific structure is shown in Figures 1 and 2. The appearance of the product adopts a split design. Figure 1 is a round hole type, which is suitable for the primary bus of a DC system to pass through. , Figure 2 square hole type, suitable for DC system when the bus is a copper bus through. According to the measurement range of the primary current and the perforation requirements, the corresponding product type can be selected. The current range of this series of sensors can be measured from 20A to 20000A. The main shapes are ф20, ф40, ф60, 64 * 16, 85 * 27, 104 * 36, 140 * 50 and other specifications. Applications.

Figure 1 Round hole type Figure 2 Square hole type

Figure 3 AHKC series open-ended Hall current sensor

1.2 working principle

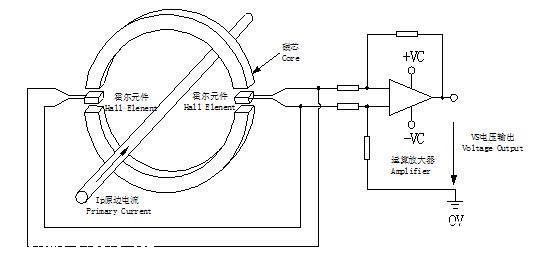

Hall current sensor is a sensor designed according to the Hall effect and electromagnetic induction principles. According to the principle, it can be divided into open-loop (direct-type) and closed-loop (magnetic balance). Open-type Hall current sensors are traditional The open-loop (direct-type) Hall sensor is improved. It is different from the traditional single iron core and single Hall chip design. In order to design a split structure, the iron cores are separated and installed symmetrically. The hardware uses dual Hall chips in parallel. Complementary differential input, open-type Hall sensor principle is shown in Figure 4:

Figure 4 Schematic diagram of the open-ended Hall sensor

When the primary current IP flows through a long wire, a magnetic field is generated around the wire. The magnitude of the magnetic field is proportional to the current flowing through the wire. The generated magnetic field is concentrated in the magnetic ring and passes through the two gaps in the air gap of the magnetic ring. The two Hall elements are measured in opposite directions and placed in the same magnetic field. The output signals have complementary characteristics. The output voltage is amplified through differential output, which can not only suppress common mode interference, but also the influence of temperature drift. The output voltage VS is accurate. Reflect the primary current IP. The normal rated output is DC ± 5V or DC4-20mA.

1.3 Product Installation

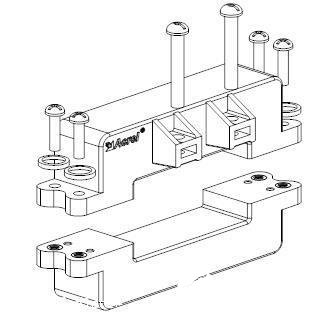

Taking a square hole product as an example, as shown in Figure 5, open the mounting screw of the open-ended Hall current sensor and remove the lower body of the sensor; install the upper body of the open-ended Hall current sensor into the primary busbar of the power distribution system , Close the lower body of the sensor, pass the mounting screws and washers of the sensor through the fixing holes of the upper and lower bodies, and fix the upper and lower bodies of the sensor together. If the installation can be powered off at the site, two corresponding threaded holes can be opened on the bronze medal according to the sensor spacing requirements, and the sensor is fixed to the busbar threaded hole through the rear mounting fixing hole to complete the installation of the sensor; The supporting rubber pad can be embedded and fixed between the shell and the bronze medal to ensure that the sensor can work reliably under vibration conditions. The entire installation process is relatively fast and simple.

Figure 5 Product installation diagram

1.4 Advantages of Open Hall Sensors

Compared with the traditional DC current measurement using shunts or transformers, open-type Hall sensors have the following advantages:

1) The primary side and secondary side have high insulation strength, up to AC 12kV isolation;

2) No insertion loss;

3) Good dynamic performance: response time is less than 20us and tracking speed di / dt is higher than 20A / us

4) It is not necessary to remove the primary cable or busbar during installation, and it is especially suitable for the reconstruction of power-off equipment.

2. Product application

Open-type Hall current sensor is mainly used in factory reconstruction DC distribution system, such as power plant DC power system reconstruction, substation DC system reconstruction, communication room renovation, railway locomotive reconstruction, etc. It can convert the DC current signal in the primary side of the system It has become a standard DC ± 5V or 4-20mA output, which has the function of monitoring and electrical isolation. It can be used with multi-circuit monitoring instruments or other electrical measuring instruments.

2.1 Application examples

From the aspect of reconstruction cost, if the traditional closed-hole Hall sensor or shunt solution is adopted, the DC bus copper bar must be removed first during construction, and then the sensor must be installed, and then the bus bar must be reinstalled and restored. At least during the entire installation process, Two construction workers cooperate in the construction, and the rectification of the line must be coordinated with power outages. If an open-hole Hall sensor solution is used, the installation method described in 1.3 requires only one construction worker, and the construction time is expected to require only the traditional solution 1/20 Time, the power outage time of the factory can be reduced accordingly, and even some occasions of continuous power construction and installation, using this solution significantly saves time, labor and labor. Comparing the purchase price of sensors, the purchase price of the same open-hole Hall sensor is slightly higher than the closed-hole Hall sensor by about 10%. From the analysis of test performance, as long as the upper and lower body screws of the sensor are tightly fixed during installation, the accuracy and stability of the open-type sensor and the closed-type sensor are basically the same.

To sum up, no matter from the superiority of on-site construction or the overall cost of overall procurement, construction and other aspects of project reconstruction, the use of open-ended Hall current sensors is undoubtedly the most cost-effective solution.

Taking the DC distribution cabinet of a well-known enterprise as an example, as shown in Figure 6, multiple DC inputs are aggregated into one current output, each of which has protection devices (circuit breakers, fuses, etc.), anti-reverse diodes, etc., and can Each voltage and current is monitored, and remote communication can be realized. 8 open-type Hall current sensors are used to monitor the DC current, and the layout is beautiful. Compared with the traditional Hall installation, it is more convenient to install and safer and more practical than the shunt scheme.

Figure 7 shows a railway locomotive reconstruction project. The reconstruction requires monitoring the DC current of the busbar without dismantling it. In this case, only the open-ended Hall current sensor scheme can be used.

Figure 6 DC distribution cabinet of a company Figure 7 A railway locomotive reconstruction project

3. Conclusion

In summary, the open-type Hall current sensor has a great role in the application of DC systems due to its good applicability such as simple structure, convenient installation, and reliable operation, especially in retrofit projects.

If you want to know more, our website has product specifications for the sensors, you can go to ALLICDATA ELECTRONICS LIMITED to get more information