What is the working principle and application of a magnetostrictive linear displacement sensor?

With the innovation of various technologies and the increasingly high requirements for the machined parts, various types of machine tools have been accelerated and flourished in recent years. Rolling Machine (Rolling Machine) is a shaping machine that bends the sheet at successive points. It has the function of rolling different shapes of sheet such as O-shaped, U-shaped and multi-section R. As a kind of shaping machine, the plate rolling machine is used to process metal plate products such as cylinders or cones. The accuracy and quality of the finished product directly affects the positioning of the value of the finished product. This has prompted the need to optimize the performance of the coiler in order to adapt to higher-end customers. The precision control of the thickness of the coil is determined by the pressing distance of the upper roll. So, how to choose a high-precision linear displacement sensor and work stably in harsh environments has become the key.

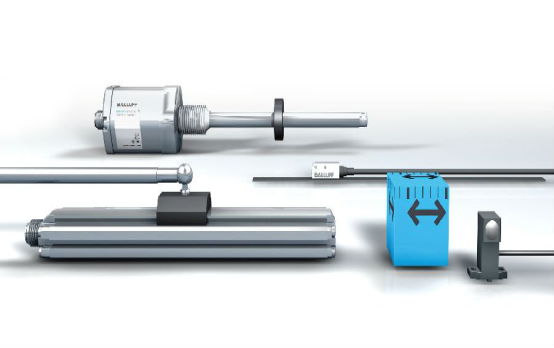

Balluff displacement sensors have non-sliding contacts, and are not affected by non-metallic factors such as dust when working. They have low power consumption and long life, and can be used under various harsh conditions. Non-contact and therefore wear-free work helps save high maintenance costs and avoids the hassle of downtime. Displacement sensors are mainly used in intelligent control of analog quantities in automated equipment production lines.

The precision of the lifting control of the rolling machine and the requirements for the magnetostrictive linear displacement sensor. In recent years, China's machine tool manufacturing industry has developed rapidly, with technological innovation and product exports increasing. Plate rolling machine has a wide range of applications in the equipment manufacturing industry, such as aerospace, military industry, automotive, shipbuilding, chemical industry, metallurgy, engineering machinery and other industries. The demand for plate rolling machine is increasing, and the accuracy of plate rolling machine is required. Higher and higher.

The plate rolling machine is driven by the vertical lifting movement of the oil cylinder to drive the upper roller. With the pressing of the upper roller and the rotating movement of the lower roller, the metal plate is continuously bent through multiple passes to produce permanent plastic deformation. Cylinder or cone. The size of the depression position needs to be feedbacked to a PLC through a linear displacement sensor to control the oil cylinder. This linear displacement sensor is the key to the accuracy of the processed plate type, which is directly related to the excellent quality of the processed product.

First, the linear measurement based on the magnetostrictive principle has the characteristics of high accuracy, high repeat accuracy, and no signal drift. By selecting Balluff's BTL6 series sensors, a resolution of 10 μm can meet the requirements for high-precision processing.

Secondly, based on its non-contact measurement method, the internal wear condition caused by the long-term operation of the sensor is avoided, which will not cause signal drift or accuracy degradation.

In addition, the all-metal casing can resist external physical factors to the greatest extent, can withstand the vibration or shock of the rolling machine at work, and isolate the erosion of oil and dust pollution sources, which greatly enhances its service life.

From an economic point of view, for a single sensor, due to different principles and manufacturing processes, the price of magnetostrictive products is higher than that of linear potentiometer products, and because of the absence of mechanical wear in the magnetostrictive linear displacement sensor, The service life is much longer than that of linear potentiometer products, and it eliminates the user maintenance costs and the loss of equipment shutdown caused by maintenance. The cost performance is obvious.

Balluff's magnetostrictive linear displacement sensor brings a whole new innovation to the control of the upper and lower rollers of the rolling machine. The accuracy of the cylinder stroke monitoring has been greatly improved. More importantly, stability and maintenance-freeness have provided guarantee for the long-term operation of the equipment, so that the performance of the rolling machine has taken a new level as a whole.

If you want to know more, our website has product specifications for linear displacement sensor, you can go to ALLICDATA ELECTRONICS LIMITED to get more information