How should I choose an electrolytic capacitor?

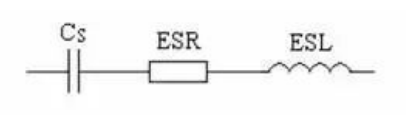

Electrolytic capacitors are one of the most important devices in primary and secondary loop filter circuits in switching power supplies. Generally, the equivalent circuit of an electrolytic capacitor can be considered as a series connection of an ideal capacitor with a parasitic inductance and an equivalent series resistance, as shown in FIG.

Figure 1 equivalent circuit of electrolytic capacitor

Ripple current tolerance

One of the most important parameters affecting the performance of electrolytic capacitors is the ripple current problem. The effect of ripple current on aluminum electrolytic capacitors is mainly due to the power consumption generated in the ESR to cause the aluminum electrolytic capacitor to heat up, thereby shortening the service life.

The ripple current on the ESR is proportional to the square of the ripple current rms, so the hourly life curve is similar to the parabolic function curve as the ripple current increases.

The method of reducing the ripple current can use a larger capacity aluminum electrolytic capacitor. After all, the large-capacity aluminum electrolytic capacitor can withstand a larger ripple current than a small-capacity aluminum electrolytic capacitor; it can also be used in parallel with a plurality of small-capacity aluminum electrolytic capacitors. A circuit topology with low ripple current can also be selected.

Reliability

The switching power supply is a DC-regulated power supply with switching control. It is widely used in various communication equipment, household appliances, computers and terminal equipment with its characteristics of small size, light weight and high efficiency.

As an input filter and smoothing aluminum electrolytic capacitor, its quality and reliability directly affect the reliability of the switching power supply. Once the aluminum electrolytic capacitor fails, it will cause the switching power supply to malfunction.

The failure modes of aluminum electrolytic capacitors used in switching regulators include breakdown failure, open circuit failure, liquid leakage failure, and electrical parameter tolerance. The breakdown failure is divided into dielectric breakdown and thermal breakdown. For electrolytic capacitors with high power and high current output switching power supply, thermal breakdown failure often accounts for a certain proportion;

Electro-corrosion causes the aluminum strip to break and the capacitor core to dry out, which makes the main mode of failure of the aluminum-electrolytic capacitor open-circuit failure of the switching power supply; the leakage is a common failure mode of the aluminum electrolytic capacitor for the switching power supply. , due to the use environment and work state is harsh, and liquid leakage often occurs. The most common failure modes of aluminum electrolytic capacitors used in switching regulators are capacitance reduction, leakage current increase and loss tangent value increase.

Summary

Capacitors that are miniaturized and bulk-capable can be achieved by using new dielectric materials such as tantalum and titanium and structural improvements. Low ESR and low ESL can be achieved through the development and optimization of new electrolytes and construction, while the product will move toward higher voltages. In the rapidly developing field of information technology, capacitors will always be one of the key components. We will continue to develop high-performance capacitors that meet the needs of the information age by applying new technologies and materials.

If you want to know more, our website has product specifications for the electrolytic capacitors, you can go to ALLICDATA ELECTRONICS LIMITED to get more information