What to do if the processor interface is wrong?

So far, we have learned how to ensure the performance and accuracy of analog sensors or conversion functions. However, in the harsh electrical industrial environment where many of these sensors are deployed, there are noise, EMI / RFI, and transient issues that affect digital electronic equipment. Therefore, it is necessary to ensure the performance of internal digital circuits and the interface connection of the system processor to ensure the robustness of data and any read and write operations.

The AD7124 starts with the following operations and features and implements this in a multi-pronged way:

• Check the performance of the master clock. When setting the output data rate, filter settling time, and filter notch frequency, the master clock is required. The main clock is checked by an independent count-up register that can be read back at any time.

• Check the number of SCLK pulses used in each SPI read and write operation through a special clock counter. This value should be a multiple of 8 (all SPI operations use 8, 16, 32, 40, or 48 clock pulses).

• AD7124 checks whether read and write operations address only valid register addresses.

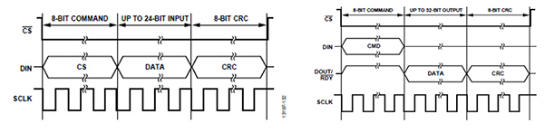

These steps deal with internal operations, but cannot ensure the integrity of the processor interface and its data. In order to provide extremely high data reliability, the user can instruct the AD7124 to implement a cyclic redundancy check (CRC) polynomial checksum algorithm. The checksum ensures that only valid data is written to the register and allows verification of the data read from the register (Figure). Please note that checksums are a high-confidence technology that can even detect single-bit errors, but cannot correct these errors.

Figure: Adding a polynomial-based CRC checksum to SPI write (left) and SPI read (right) transactions to detect single-bit errors.

When enabled, this operation will calculate the checksum of the data block and append it to the end of each read and write transaction. In order to ensure that the register write is successful, the register needs to be read back to verify whether the stored checksum is consistent with the checksum calculated from the data.

In harsh electrical environments, even memory may have bit errors. In order to perform an advanced check for such errors in the on-chip registers, the AD7124 calculates the checksum for a series of operations in the following situations each time:

• When there is a register write cycle

• When there is offset / full-scale calibration

• When the device performs a single conversion cycle and the ADC enters standby mode after the conversion is complete

• When exiting the continuous reading mode

To enhance robustness, internal read-only memory (ROM) is also evaluated. At power-up, all registers are initialized to the default values stored in ROM. At this time, the CRC calculation is performed on the ROM content. If the calculated value is different from the stored CRC result, it indicates that there is at least one single-bit error.

The AD7124 can also provide excitation for many types of sensors, and can adjust and scale the sensor output signal through amplifiers and PGAs. In order to provide extremely high robustness, the AD7124 contains many internal registers for initialization, establishing the required functional modes and parameters, and flagging various errors and faults.

Quickly start an AD7124 design using the AD7124 evaluation board

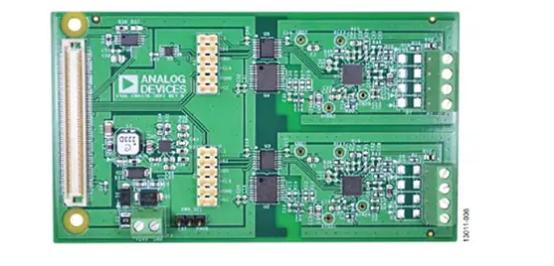

The AD7124 is a complex system with many design possibilities and performance. It is not a simple "plug and play" sensor interface IC. To facilitate learning and enable designers to quickly familiarize themselves with various potential functions, Analog Devices also provides the EVAL-CN0376-SDPZ evaluation board (Figure).

Figure: The EVAL-CN0376-SDPZ evaluation board accelerates the speed of design imports and allows full use of the many functions and features of the AD7124.

The evaluation board contains the power supply and external components needed to connect the AD7124 to various actual sensors and processors. The board is supported by the CN-0376 evaluation software based on Windows PC, which communicates via the USB port to configure and capture the data in the evaluation board.

If you want to know more, our website has product specifications for processor interface, you can go to ALLICDATA ELECTRONICS LIMITED to get more information