Electromagnetic interference of LED drive power

First, let's look at several factors that can affect EMI/EMC: the circuit structure of the drive power; switching frequency, grounding, PCB design, reset circuit design of intelligent LED power supply. Since the original LED power supply is a linear power supply, the linear power supply consumes a large amount of energy in the form of heat when it is operating. The linear power supply works in such a way that he must have a pressure device from high voltage to low voltage, which is generally a transformer, and then rectified to output DC voltage. Although it is bulky and has a large amount of heat, the advantage is that the external interference is small, the electromagnetic interference is small, and it is easy to solve. Nowadays, more LED switching power supplies are used, and the LED driving power supply in the form of PWM is to make the power transistor work in the on and off states. When turned on, the voltage is low and the current is large; when turned off, the voltage is high and the current is small, so the loss generated on the power semiconductor device is also small. The disadvantage is that electromagnetic interference (EMI) is also more serious.

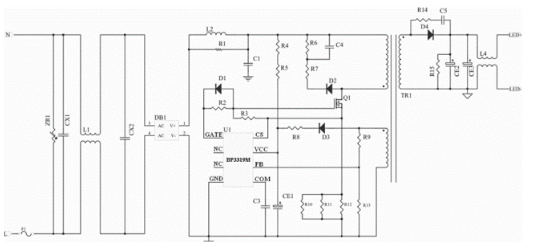

The problem of electromagnetic compatibility of the LED power supply is generally in the power supply of the switching circuit. The switching circuit is one of the main sources of interference for the switching power supply. The switching circuit is the core of the LED driving power supply, and the switching circuit is mainly composed of a switching tube and a high frequency transformer. It produces a du/dt with a large amplitude pulse, a wide frequency band and a rich harmonic. The main reason for this high-frequency pulse interference is that the switching tube load is the primary coil of the high-frequency transformer and is an inductive load. At the instant of conduction, the primary coil generates a large inrush current and a high surge spike voltage appears at both ends of the primary coil; at the moment of disconnection, part of the energy is not transmitted from the primary coil to the second due to the leakage flux of the primary coil. In the secondary coil, a decaying oscillation with a spike is formed in the circuit, superimposed on the turn-off voltage to form a turn-off voltage spike. High frequency pulses produce more emissions and periodic signals produce more emissions. In an LED power system, the switching circuit produces a current spike, which also produces a current spike when the load current changes. This is one of the root causes of electromagnetic interference.

Basically in all the problems of electromagnetic interference problems, mainly due to improper grounding. There are three ways to signal ground: single point, multiple points, and hybrid. When the switching circuit frequency is lower than 1MHz, a single-point grounding method can be used, but it is not suitable for high frequency; in high-frequency applications, multi-point grounding is preferred. Hybrid grounding is a method in which the low frequency is grounded at a single point and the high frequency is grounded at multiple points. The ground wire layout is the key, and the grounding circuit of the high-frequency digital circuit and the low-level analog circuit cannot be mixed. It can be said that proper printed circuit board (PCB) wiring is critical to preventing EMI. In the LED power supply, there are many intelligent LED power supplies that are controlled by single-chip microcomputers, and some LED power supplies use a single-chip microcomputer to control the duty cycle of the switching circuit. The watchdog system of the single-chip microcomputer plays a particularly important role in the operation of the entire LED power supply, due to All sources of interference cannot be isolated or removed. Once the CPU interferes with the normal operation of the program, the reset system combined with software processing becomes an effective barrier to error correction.