How to design a LED lighting solution based on a high power?

With the accelerated pace of urban construction, leisure squares and green parks are the highlights of the city, representing the urbanites' desire to return to nature. Water represents spirituality. Waterscapes and fountains are an integral part of leisure squares and green parks, so the demand for underwater lights is considerable. At present, colored underwater lights are generally traditional PAR lights, which require additional filters to produce various colors, which greatly reduces the luminous efficiency. It can be seen from the comparison that in the red, green and blue underwater lights, the total luminous flux of the traditional lamps is 1 to 2 times that of the LED underwater lights. The LED packaging technology determines that the direction of the light source is very strong, and the LED volume is very large. It is small and can be matched with optical lenses of various angles. These characteristics determine that the power consumption of traditional underwater lights is more than 13 times that of LED underwater lights. This shows that the energy-saving effect of LED underwater lights is quite significant. In addition, the spectral distribution of the LED determines its light color purity and saturation that are unmatched by traditional PAR lamps, so it has a strong competitive advantage.

For example, the LT3474 and LT3475 are high-voltage, high-current, single-channel and dual-channel buck LED converters with wide PWM dimming ratios, capable of driving one or more LEDs with currents up to 1A and 1.5A, so that Each LED achieves a brightness of 80 lumens to 120 lumens (this value will be higher when LEDs with higher output are available). These dedicated LED drivers have onboard high-voltage NPN power switches and internal detection resistors, designed to maximize board space, reduce component count, and simplify design.

With its high-end detection resistors, the LT3474 and LT3475 can drive grounded LEDs, which is an important advantage in many systems. Current-mode control and an accurate reference voltage optimize the loop dynamics to achieve a well-adjusted, constant LED current with low ripple. The thermally enhanced bare pad package can maintain a low junction temperature during high power operation in a stress environment. A PWM pin uses a dimming MOSFET gate signal to expand the dimming ratio of the converter. The method is to maintain a constant output capacitor voltage and control the loop state during the PWM dimming off time. Shutdown and external analog current regulation pins provide a simple interface for greater LED light and current control flexibility in any system.

Single-channel step-down 1A LED driver

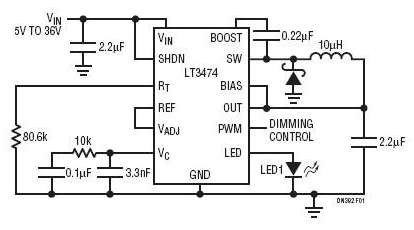

The LT3474 buck converter 1ALED driver shown in Figure 1 has the characteristics that make it suitable for automotive applications (and other battery-powered applications) or industrial applications where board space is limited, high voltages and high ambient temperatures exist. This circuit uses a high-end integrated 100mΩ detection resistor (to achieve true LED current detection and regulation), compared to the common inefficient method of biasing the LED with a constant voltage and an energy-consuming bias resistor. Its performance is more superior. The input voltage range of 4V to 36V makes it ideal for use with protection circuits with very small (or no input) transients in automotive, industrial, and aerospace applications. In these applications, long cables from the battery can High input spikes.

Figure 1 LT3474 high voltage buck LED driver can adjust 1A current

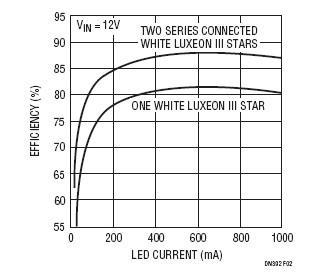

In 1 LED and 2 LED applications, the boost NPN power switch achieves high efficiency (Figure 2). The integrated boost diode is designed to further reduce the number of components. Driving the shutdown pin to ground will turn off the LED and change the brightness of the LED from 400: 1TrueColorPWM? Dimming and an external MOSFET driver or use an analog 25: 1 (or filtered PWM) signal on the VADJ pin to control. The switching frequency can be set in the range of 200kHz to 2MHz through an external resistor, so the application can be optimized for the highest efficiency or the smallest component size.

Figure 2 LT3474 buck converter can efficiently drive a single or multiple LEDs

The maximum output voltage of the LT3474 is clamped at 13.8V, which prevents the LED of the LT3474 output from being open. Short-circuit protection is the last function of LT3474 to become a "bullet-proof" converter under various LED fault conditions. Dual-channel step-down 1.5A LED driver.

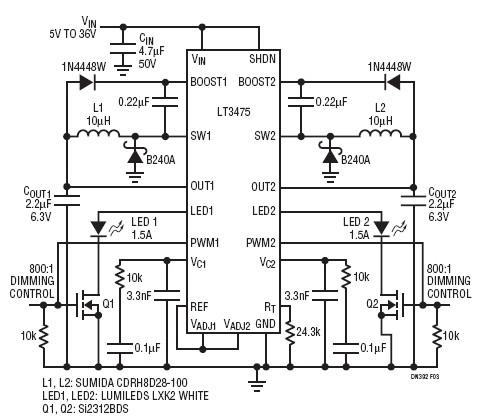

Figure 3 shows a dual 1.5A step-down converter LED driver using LT3475. It basically integrates two LT3474 converters into a single IC and adds a small number of components. This simple solution is ideal for automotive applications that require two ceiling lights or dashboard lights in the same system. Both lamp channels (each a single LED or a string of LEDs) have separate VADJ voltages and PWM signals for independent operation, but a single shutdown pin can reduce the total battery leakage current of the circuit in shutdown mode To 2μA, which further improves the micropower operation that saves battery power.

Figure 3 LT3475 dual-channel high-voltage step-down LED driver adjustable 1.5A circuit

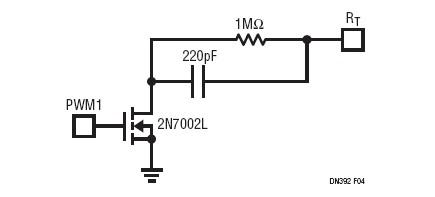

For higher power LEDs or LEDs that require higher currents and lower forward voltages (for example: red or light yellow brake and signal LEDs), each of the two outputs can be operated with up to 1.5A drive. Although the maximum output voltage of the LT3475 is clamped at the level of 13.8V like the LT3474, its maximum power output capability is three times. The PWM dimming ratio is also higher (up to 1200: 1) or use the extended dimming ratio circuit in Figure 4 to increase to a higher ratio). Improvements in the PWM dimming method and lower minimum dimming on-time requirements help the IC achieve extreme automotive and night dimming levels while maintaining the same true color as at 100% duty cycle. The independent simulated VADJ dimming ratio for each channel is 30: 1 (50mA LED current). To reduce internal power consumption, the boost diode for each channel is not integrated into the IC.

Figure 4 When added to the circuit shown in Figure 3, the LT3475's extended dimming range circuit provides 1200: 1

PWM dimming ratio, and can be as high as 3000: 1 under the frequency condition of 1.4MHz Compared with LT3474, LT3475 provides three times the power output capability, the same shutdown current, the same switching frequency range, a slightly higher input voltage (operating voltage is 36V, maximum value is 40V), higher dimming ratio, Higher LED current and only a slightly larger package (LT3474 uses a 16-pin exposed thermal pad TSSOP package, while LT3475 uses the same type of 20-pin package), making it a high-power solution Excellent choice. In addition, the inverting switching of the two channels in the LT3475 also reduces the input ripple on the power supply and limits the need for additional high-voltage input capacitors.

In conclusion

The application amount of architectural glass in modern buildings is increasing, the variety is more and more, and the functions are more and more complete. The application amount, application type and function of architectural glass in architecture can be used as one of the criteria for evaluating the modernization degree of buildings. In particular, the decorative performance of architectural glass can be said to be ever-changing. Without architectural glass, there is no modern building. However, due to the glass's ability to transmit light, as well as the optical properties of reflected light and absorbed light, the landscape lighting design supporting the building has entered a pattern.

How can the light be used to reproduce the beauty of the glass during the day? This is a general concern of landscape lighting designers. For the lighting treatment of modern buildings with large-area glass, "architectural lighting" is used to integrate light-emitting devices (light sources) and building components. Refreshing. The high-power LED has high single light efficiency, small unit volume, and great design flexibility, which can best match the structural characteristics of the light carrier and is easy to install, providing a new lighting solution for such buildings.

If you want to know more, our website has product specifications for LED lighting, you can go to ALLICDATA ELECTRONICS LIMITED to get more information