OLED illumination principle and structure

OLED's principle of illumination and display drive are similar to LEDs. The main purpose is to make the electrons and holes from the positive and negative electrodes respectively, and inject them into the two electrodes (the anode is ITO conductive glass mold, and the cathode is Mg, Al). The organic thin film regions of Li, Li, etc., cause luminescence due to the encounter (the color of the luminescence depends on the material of the organic luminescent layer). The organic thin film region includes an electron transport layer, an organic light emitting layer, a hole transport layer, and a hole injection layer. The "hole transfer layer" is added by some manufacturers to increase the efficiency of the luminescence phenomenon, and the "electron transfer layer" which is added between the negative electrode and the luminescent layer is for increasing the luminance and quantum efficiency of the organic material and lowering the starting voltage.

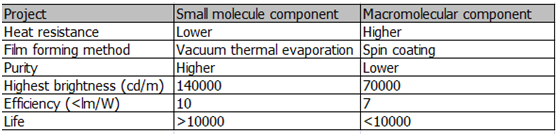

The organic electroluminescent device can be roughly classified into two types, a molecule-based device and a polymer-based device, depending on the organic film material used. Small molecule components are based on dyes and pigments, and the molecular weight is generally about several hundred. The polymer components are made of conjugated polymers, and the molecular weight is between tens of thousands and millions. Among them, the small molecule organic electroluminescent component is called OLED, and the polymer organic electroluminescent component is called PLED.

Table 1. Comparison of characteristics of small molecular components and polymer components

The above two types of systems have their own advantages and disadvantages. OLED is based on low molecular weight dyes and pigments. The main technology is vacuum evaporation to deposit organic chemical materials on glass, because it is easy to colorize and autoclave. The process technology is mature, and it is easier to synthesize and purify the materials, so there are more manufacturers.

In the aspect of PLED, it is a conjugated polymer as a material, and the process is a coating technique, and an organic chemical substance is applied. Therefore, whether the material can be stably obtained is the most important key technology, and the PLED is similar to a semiconductor process in the process. Therefore, the mass production capability is superior to OLED. If the PLED yield is stable, it will be able to obtain an advantage in cost.