How to compare the three mainstream haptic feedback technologies: ERM, LRA, and piezoelectric?

Haptic feedback is not a new technology. Back in the 1960s, we can find the first device change that used vibration feedback to send information to users. The systems used to generate vibrations in the past are still used to generate basic tactile feedback in low-cost devices.

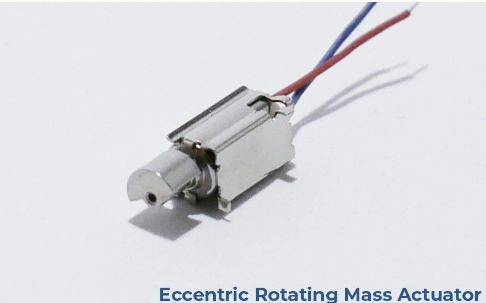

Long history, low cost vibration feedback solution

Eccentric rotaTIng mass (ERM) is usually called a vibration motor. This haptic system consists of a motor that rotates an eccentric mass at high frequency. From the 1960s to the present, the same concept is still in use, but this technology has been miniaturized to accommodate smaller devices.

With the advantage of low cost, eccentric rotating mass actuators are still used in many devices to generate haptic feedback, but they are beginning to be replaced by more efficient technologies. Today we live in a digital world, surrounded by various devices with touch screens. In order to improve the user experience of devices, companies around the world are developing new technologies, and therefore, better touch technologies are also evolving.

Piezoelectric hapTIc actuator is one of the high-performance technologies. Based on the piezoelectric effect of certain materials, this technology has more advantages than ERM motors. Piezoelectric solutions do not need to rotate the eccentric mass, but need to use a piezoelectric actuator, which sends high voltage power through the actuator material of the piezoelectric actuator, deforms it and generates tactile feedback. Next, we will understand the difference between piezoelectric and ERM haptics, and the haptic technology you should use in your application.

Piezo haptics vs. ERM haptics

The acceleration in haptics is related to the strength of the haptic feedback you feel; the higher the acceleration that the actuator can achieve, the stronger the haptic feedback it produces.

The achievable acceleration of the ERM system is quite limited, and the reason is easy to understand: the motor needs to accelerate the mass to produce vibration. Therefore, it needs to break the mass inertia and increase the speed to the optimal frequency. However, the acceleration of the mass is not instantaneous, which is why the ERM motor rumbling due to inaccuracy.

On the other hand, piezoelectric actuators have no mechanical limitations. Since vibration does not rely on mass rotation, once the high voltage reaches the piezoelectric material, the actuator will vibrate, so the piezoelectric actuator can produce stronger and clearer feedback than the ERM motor. In addition, taking Boréas Technologies’ piezoelectric CapDrive technology as an example, the ERM solution consumes 20 times more energy

Power consumption: ERM vs. CapDrive technology piezoelectric haptics.

The main advantage of piezoelectric haptic technology in other areas is total power consumption. Piezoelectric actuators are very efficient. Unfortunately, the low power consumption of the actuators is offset by poorly efficient piezoelectric actuators. The situation has changed since the release of CapDrive technology. The first piezoelectric haptic driver IC with CapDrive technology (BOS1901), which is known as the most efficient piezoelectric driver on the market. If you want to integrate touch into power-constrained devices (such as mobile devices), piezoelectric haptic technology It is a better choice than ERM solutions.

The piezoelectric response is almost instantaneous, and the vibration motor has a slower response time

Haptic feedback needs perfect timing to produce the best feedback. The faster the response time, it can be transformed into clearer and more precise tactile feedback. Vibrating motors take longer to accelerate the rotating mass and reach its peak frequency (the best feedback area); in addition, they have to decelerate the mass after reaching the effect. ERM usually takes up to 50 milliseconds (ms) to reach the peak frequency , The delay of acceleration and deceleration will produce slight undesirable vibrations at the beginning and end of the peak.

The real-time response time of the piezoelectric actuator is less than 2 ms, which means you can hardly feel the slight bad tactile feedback during acceleration and deceleration. Piezo touch produces clearer and more precise feedback. The limiting factor of piezoelectric actuators is actually the response time of piezoelectric actuators. The response time of the BOS1901 piezoelectric actuator is less than 6ms.

Piezo haptic technology saves a lot of space than ERM systems

Compared with piezoelectric haptic solutions, ERM vibration motor haptic systems are larger and take up more space. Although ERM drives are indeed smaller than piezoelectric drives, the biggest difference is the size of the actuator. Piezo actuators are smaller than ERMs and provide greater tactile feedback.

If you need a compact solution, piezoelectric touch is a better choice than a vibration motor.

If you want to know more, our website has product specifications for ERM, LRA, and piezoelectric, you can go to ALLICDATA ELECTRONICS LIMITED to get more information