The main performance advantage of LDC1000 is the number?

Regarding the existing sensing technology, whether it is a high-end sensitivity, high-precision ultrasonic sensor, or a low-end, low-cost switching sensor, the LDC1000 can perform these tasks.

The working principle of LDC1000

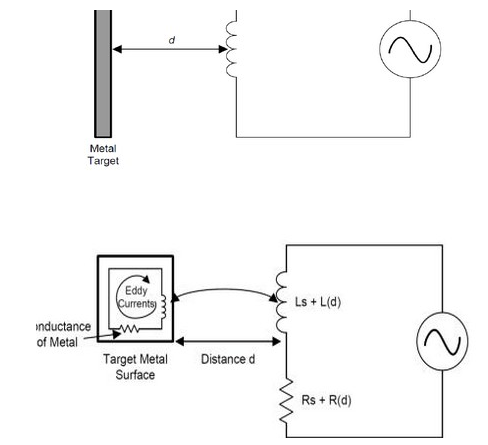

The detection principle of LDC1000 inductance is to use the principle of electromagnetic induction. When an alternating current is added to the coil, an alternating magnetic field will be generated around the coil. At this time, if a metal object (1) enters this magnetic field, an eddy current will be generated on the surface of the metal object. The direction of the eddy current is opposite to that of the coil current. The induced electromagnetic field generated by the eddy current is opposite to the electromagnetic field of the coil. Eddy current is related to the magnetic permeability and electrical conductivity of the metal body, the geometry of the coil, the geometric size and the distance from the head coil to the surface of the metal conductor.

The magnetic field in the opposite direction generated by the eddy current is coupled with the coil, as if there is another secondary coil. In this way, the coil of LDC1000 forms a transformer as the secondary coil.

Transfer files for [membrane switch] proofing

LDC1000

Transfer files for [membrane switch] proofing

Let Ls be the inductance value of the primary coil and Rs be the parasitic resistance of the primary coil. L(d) is the mutual inductance, R(d) is the parasitic resistance of the mutual inductance resistance, where d is a function of distance.

If the alternating current is only applied to the inductance (primary coil), it will also consume a lot of energy while generating an alternating magnetic field. At this time, a capacitor is connected in parallel to the inductor, and the energy loss is greatly reduced due to the parallel resonance effect of the LC, and only the loss is in Rs and R(d). It can be seen that when the loss of R(d) is detected, d can be detected indirectly.

It can be seen from the above that LCD1000 does not directly detect series resistance, but detects equivalent parallel resistance.

LDC1000

Transfer files for [membrane switch] proofing

The main performance advantages of LDC1000:

Another sensor in the industry, inductive sensors are also widely used in industrial fields. Inductive sensors have a series of advantages such as simple structure, reliable work, high measurement accuracy, stable zero point, and large output power. The main disadvantages are sensitivity, linearity and The measurement ranges are mutually restricted. However, the frequency response of the sensor itself is low, which is not suitable for fast dynamic measurement. However, this is not the most fatal shortcoming of inductive sensors, but must go through a conversion circuit to output electricity. Therefore, for most engineers, the difficult-to-adjust conversion circuit is a stumbling block that hinders the popularity of inductive sensors. However, this inductance-to-digital converter launched by TI does not require a complicated conversion circuit and directly outputs a detectable digital signal from the LDC1000.

Higher resolution: 16-bit resonance impedance and 24-bit inductance value can be used to achieve sub-micron resolution in position sensing applications;

Higher reliability: Provide non-contact sensing technology to avoid the influence of non-conductive pollutants such as oil and dust, which can extend the service life of the equipment;

Higher flexibility: allow the sensor to be placed far away from the electronic product, in a position where the PCB cannot be placed;

Lower system cost: using low-cost sensors and conductive targets, no magnets required;

Infinite possibilities: support for compressed metal flakes or conductive ink targets, which can bring infinite possibilities for creative and innovative system design;

Lower system power consumption: power consumption is less than 8.5mW in standard operation, and less than 1.25mW in standby mode.

"The inductance-to-digital converter is a new way of sensing the current operating position and motion. It can provide better performance, higher reliability, higher flexibility, low cost, and low power consumption. Very low," Baldwin said.

Specific applications include detecting the speed, position, gear position, rotation speed, angle, etc. of all magnetic objects. Target applications include industrial, automotive, consumer, medical, computing and mobile equipment, and communications fields. Specific applications range from simple buttons, knobs and switches to high-resolution heart rate monitors, turbine flow meters, and high-speed motor/gear controllers.

If you want to know more, our website has product specifications for LDC, you can go to ALLICDATA ELECTRONICS LIMITED to get more information