Common electric iron type and structure

1.Internal heat type soldering iron

The iron head of the internal heat type soldering iron is inserted on the iron core, which has the characteristics of fast heat generation and high efficiency. According to different power, it can be used after power on 2~5 minutes.

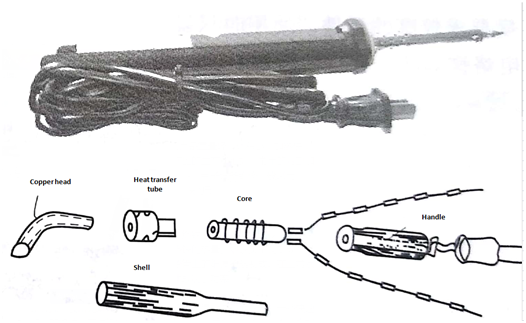

The iron head can reach a temperature of around 350 °C. The advantages are light weight, small volume, fast heating, low power consumption and high thermal efficiency, so it is very suitable for the production and maintenance of electronic products. Commonly used internal heating soldering irons are available in 20, 25, 30, 50W and many other types. Electronic equipment repair generally uses 20~30W internal heating type soldering iron.Figure 1 shows the shape and structure of the hot soldering iron.

Figure 1 the shape and structure of the internal heat type soldering iron

the internal heat type soldering iron is composed of a casing, a handle, a soldering iron head, a soldering iron core, a power cord, etc., and the handle is made of heat-resistant glued wood, and the handle is not damaged by the heat of the soldering iron. The soldering iron head is made of copper, and its quality is very much related to the quality of the soldering. The iron core is made of a fine nickel-chromium wire on a porcelain tube. In the normal state, its resistance value can be 1~3kΩ depending on the power.

The iron core shell is generally made of seamless steel pipe, so it will not be deformed due to excessive temperature. Some fast-heating soldering irons are made of brass tubes. Due to the fast heat transfer, it is not suitable for long-term power-on, otherwise the handle will be damaged. The binding posts are made of copper screws to hold the core and power cord.

2. External thermal soldering iron

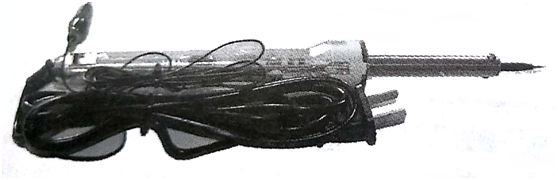

The external heating type soldering iron is composed of a soldering iron head, a heat transfer tube, a soldering iron core, a casing, a handle and the like. The iron core is wound around the tube of the thin mica plate with a resistance wire, and the iron core is placed outside the soldering iron head, so it is called an external heating type soldering iron.

The external heating type soldering iron has a longer heating time, and the higher the power, the slower the heat. The power is 30~300W. The volume is relatively large and relatively heavy, so it is used less in the repair of small appliances, and is often used to weld large metal parts. The use and repair methods are the same as the internal heat type.

Figure 2 external thermal soldering iron internal structure

3. Electronic constant temperature electric soldering iron

The electronic constant temperature electric soldering iron is provided with a temperature control circuit on the basis of the foregoing soldering iron to make the electric soldering iron constant temperature, and is suitable for welding without a high temperature requirement. When using the temperature control knob, the temperature can be reached. Others are the same as the to above. The electronic constant temperature soldering iron is shown in Figure 3.

Figure 3