What are the design challenges and effective solutions for high-voltage battery packs?

The Green Revolution may soon usher in a major victory. When large-scale electrical energy becomes "storable" and "portable" energy, energy efficiency will be significantly improved, and the promotion of renewable energy will also progress. Storage and portability are the main advantages of liquid fuels, and the power provided by battery systems has the potential to provide a viable alternative. Electrical energy can be used in almost all energy-consuming equipment, and electrical energy can also be generated from almost all available energy sources. Nuclear energy, solar energy, wind energy, geothermal energy and liquid fuels (gasoline, diesel, ethanol, hydrogen, etc.) can be easily converted into electrical energy. Therefore, the major advantage of electricity compared to petroleum fuels is that the most cost-effective solution can be used to generate energy anytime, anywhere.

The standardization of electrical energy can simultaneously achieve economies of scale and eliminate the infrastructure needed for local fuel consumption. The superior storability of electrical energy facilitates power generation (the highest efficiency and is not of the "on-demand" type), which is currently the case. For example: wind power and solar power may not be consistent with the peak power demand mode, and the storable characteristics can alleviate this problem. The superior portability allows electrical energy to be used as energy for automobiles (large energy consumers). Over time, other applications that tend to use green energy will definitely benefit from this technology.

Electric vehicle requirements for battery systems

Electric vehicles provide a huge development opportunity for the green revolution for many reasons. Electric vehicles use grid power instead of gas power. The power generation efficiency of the grid is very high and can be obtained from almost all energy sources. In addition, the energy efficiency of electric vehicles is also higher than that of fuel vehicles. Most vehicles will experience a continuous cycle of "acceleration, deceleration and idling" while running. In contrast, variable loads (such as acceleration or deceleration) are more beneficial to electric motors (rather than fuel engines) because they provide high torque at low speeds. The working efficiency of the fuel engine only reaches the highest within a narrow speed / load range, and in order to meet the needs of peak acceleration, it must be very large. The efficiency of an engine used to convert gasoline energy into kinetic energy is usually 20%, while the electric motor can achieve a typical efficiency of 90% during the conversion of electrical energy into kinetic energy. In addition, the electric motor does not need to consume energy unnecessarily because of idling when parked, and the electric system also has the potential to restore mechanical energy through regenerative braking. Through the fact that the typical energy cost of electric vehicles is only $ 0.013 / mile, the overall improvement in energy efficiency can be seen.

Unfortunately, in today's market, pure electric vehicles are not yet a viable solution because their driving distance is limited by the energy that can be stored on the vehicle. Today's common battery pack can drive an electric car for 100 miles after 8 hours of charging. An ordinary car fuel tank can provide a standard car with a driving distance of 300 miles, and it only takes a few minutes to complete the refueling. If it is to be widely accepted by American consumers, then electric vehicles must extend the driving distance and / or shorten the recharging time. The solution that came into being is the “hybrid hybrid electric vehicle”, which combines a fuel engine and an electric drive system to provide sufficient driving distance while still having most of the benefits of green energy. A hybrid electric vehicle uses an on-board gas engine (for battery charging) and operates the engine within the most effective speed / torque range when needed.

There is no doubt that the success of electric vehicles will help other applications of high-performance battery systems find their own living space, thereby promoting their price decline and performance improvement. For local power generation (including small photovoltaic or wind power generation systems), the battery can play a vital balancing role, and when grid power can be used, it can also serve as a backup power system. Current battery systems are quite expensive and bulky, and have reliability and safety issues. The next-generation battery system will provide higher energy density, aiming to achieve a smaller form factor, lower price, higher reliability and safety solutions.

High voltage battery design challenges

For high-power battery applications, lithium ion batteries can be used as the preferred chemical battery, mainly because of its high energy density. Today's electric vehicles and hybrid electric vehicles use NiMH batteries. If lithium-ion batteries are used, their energy storage density will increase by 400%. However, in order to maintain the reliability of lithium ion batteries during thousands of charge and discharge cycles, the battery system must solve many technical problems.

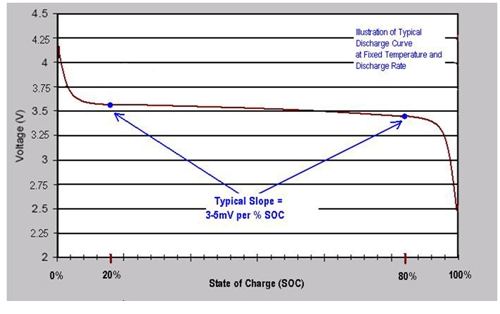

Lithium-ion battery performance depends on battery temperature and lifetime, battery charge and discharge rate, and state of charge (SOC). These factors are not independent. For example: Lithium ion batteries will generate heat during discharge, thereby increasing the discharge current. This may cause a thermal runaway state and lead to catastrophic failure. In addition, charging a lithium ion battery to 100% SOC or discharging to 0% SOC will quickly reduce its capacity. Therefore, the operation of lithium-ion batteries must be limited to a certain SOC range, such as 20% to 80%, and the available capacity at this time is only 60% of the specified capacity. Not only that, lithium-ion batteries also have a flat discharge curve (Figure 1), where the 1% SOC change may only appear as a voltage difference of a few millivolts. To fully utilize the battery's available voltage range, the battery system must monitor the battery voltage very accurately (it directly corresponds to the SOC).

In addition to the sensitive characteristics of lithium-ion batteries, the method of combining batteries is also an important consideration. If you want to provide effective power from an electrical system (such as the electrical system used to accelerate the vehicle), you need a voltage of up to hundreds of volts. For example, delivering 1kW of power at 1V requires 1,000A of current, while delivering 1kW of power at 100V requires only 10A of current. The inherent resistance in the system wiring and interconnections will be converted into IR losses, so designers need to use the highest practical voltage / lowest current.

If you want to know more, our website has product specifications for battery, you can go to ALLICDATA ELECTRONICS LIMITED to get more information