What is laser displacement sensing technology?

New solutions for laser sensing

Based on this current situation, Zhiguangzi relies on the core team’s deep technical accumulation in the field of optoelectronic communication, and uses the advantages of integrated optical chip technology to develop a small laser sensing platform that combines these two mainstream sensing functions in one optical On the platform, multiple functions such as displacement measurement and vibration measurement can be realized, while maintaining high-precision measurement, it also greatly reduces the size and cost of the module.

At present, optical components are usually bulky and expensive, and the connection process with other electronic components requires a customized and accurate assembly process. The integration of optical components enables it to achieve more complex designs and more functions on the basis of low cost. Integrated optical chips can contain dozens to hundreds of optical components on a single optical substrate, including lasers, modulators, photodetectors, and filters. It has now become an effective solution for existing and emerging markets. Provide innovative optical modules. With the increasing demand for optical sensor technology in modern manufacturing, integrated optical chips can simplify system design, allowing sensors to perform faster and more accurate measurements at lower cost.

Schematic diagram of the small laser sensing platform of Zhiguang

As shown in the schematic diagram of the sensor platform, optical interferometers with different delay lines were first implemented on integrated optical chips, and integrated optical chips, laser diodes, detector arrays and optical lenses were combined into a miniaturized package through an integrated package Laser sensor module. The laser sensor platform independently researched and developed by Zhizhiguangzi through a proprietary digital signal processing (DSP) algorithm can provide various functions such as instantaneous displacement, vibration and optical phase measurement in the LDV technology. In addition, it can also achieve the same as the conventional triangulation laser The absolute displacement/distance measurement is the same as the displacement sensor, and has the same or even better measurement accuracy.

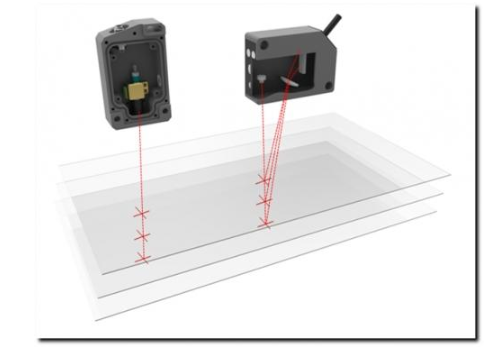

Comparison of laser coaxial displacement sensor (left) and traditional triangulation laser displacement sensor (right)

Based on this miniaturized laser sensing platform that combines instantaneous displacement, vibration, optical phase measurement and absolute displacement/distance measurement, Zhizhiguangzi has also developed a series of laser sensing modules (see picture).

It is understood that the MX-G series laser coaxial sensor independently developed by Zhiguangzi adopts the self-developed nonlinear frequency modulation continuous wave modulation and demodulation (FMCW) technology, based on the principle of optical coherent reception, with extremely low optical power (output at a distance of 15cm Optical power only needs 5mW), wide dynamic measurement range (can measure objects within a range of a few centimeters to 4 meters), high measurement accuracy (displacement measurement 1 meter away, repeatability is usually less than 0.01μm), strong anti-interference ( It is only sensitive to the wavelength of its own light source and can resist any interference from ambient light), laser coaxial design (can measure objects that are difficult to measure with traditional triangulation sensors, such as blind holes), and high sensitivity. The MX-G series sensor can measure a very wide distance and range, but it can maintain the same accuracy as the short-distance measurement, which cannot be achieved by the traditional triangulation method.

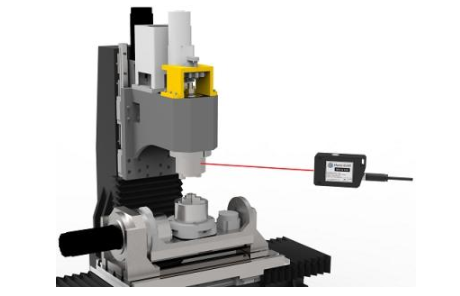

MX-G series laser coaxial displacement sensor

The technical staff of Zhiguangzi introduced to OFweek laser network that the key component of the MX-G series laser coaxial displacement sensor is its optical module. It consists of laser, photodetector (in package), integrated optical chip and optical lens. The optical lens is adjustable and can be replaced according to different applications. The standard lens (diameter 8.5mm) is suitable for a focused beam of 150mm with a spot radius of 0.05mm. When the measuring distance is 2 meters, the spot radius is about 1mm. If the user needs, it can also support collimation configuration. For example, install a lens with a diameter of 6.5mm and support collimated measurement, with a spot radius of 3.5mm, which can meet the needs of users for collimation measurement and smaller spot at the same time. A particularly outstanding point is that this technique can achieve deep hole measurement that cannot be done by triangulation.

Deep hole inspection diagram

In addition, the MX-G series laser coaxial vibration sensor can achieve nanometer-scale remote and accurate vibration measurement. The frequency range and amplitude sensitivity of the vibration measurement are comparable to those of commonly used LDVs. It has integrated optical transceiver, coaxial measurement, easy installation, and anti-interference. Strong, not affected by dust or changes in the light intensity of the measuring surface, and can be used for horn amplitude detection, bearing vibration detection, lathe vibration monitoring, automobile vibration detection, etc.

Vibration detection diagram

As introduced at the beginning of the article, this type of sensor can directly measure the thickness of transparent objects (such as film, glass plate or glass lens) in displacement measurement mode, and can be peeled and bent in vibration measurement mode (also a phase measurement mode) Rapid detection of degree.

This article is from Allicdata Electronics Limited which offer electronic components, semiconductors, antennas, capacitors, connectors, diodes, transistors, IC,resistors. For more product information, please go to the website to get it.