What needs can MEMS gas sensors meet in various applications?

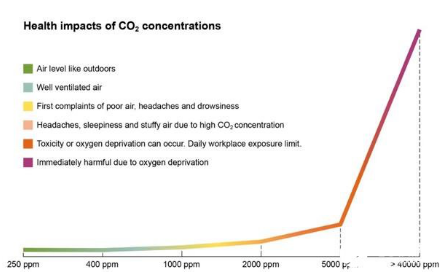

According to Mymes Consulting, CO2 (carbon dioxide) concentration is a key indicator of indoor air quality.

Good air quality can make the people in them more energetic and more productive. Excessive CO2 concentration means poor indoor air quality, which is often caused by insufficient air conditioning and air recirculation. This condition can lead to well-documented health problems such as Sick Building Syndrome (SBS). Fine dust, mold, pollen, bacteria, and even other indoor toxins such as asbestos can also affect health.

CO2 limits prevent disease

Over the years, due to human activities, the concentration of greenhouse gases and CO2 in the environment has gradually increased; today the value in the environment is slightly higher than 400 ppm (0.04%), which represents healthy fresh air. Indoors, CO2 concentrations of up to 1000 ppm (0.1%) are still considered acceptable, and this can be achieved with a good supply of fresh air. From a scientific point of view, CO2 concentration values are vital to health, as higher CO2 concentrations can have long-term negative effects on the human body.

Health effects of high CO2 concentrations

Even if the CO2 concentration is in the range of 1000 ppm (0.1%) to 2000 ppm (0.2%), the difference in air quality is obvious, and people will feel tired in such an environment. If CO2 concentrations continue to rise, people will feel stuffy, headaches, drowsiness, decreased concentration, and increased heart rate. Therefore, the World Health Organization recommends that the indoor CO2 concentration be controlled to within 1000 ppm (0.1%) as much as possible. The United States Environmental Protection Agency (EPA) clearly recommends that outdoor air circulation be used to improve indoor air quality. HVAC can be used to integrate heating, ventilation, and air conditioning.

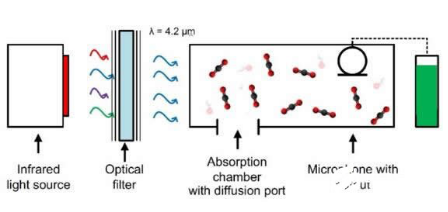

MEMS gas sensor based on photoacoustic spectroscopy

Infineon successfully developed a new CO2 sensor based on photoacoustic spectroscopy (PAS) based on its MEMS microphone design experience and experimental process. PAS is a physical method that is suitable for detecting gas components in mixtures, such as CO2 concentration in indoor air.

Schematic of CO2 sensor based on photoacoustic spectroscopy

Photoacoustic spectroscopy is based on the fact that gas molecules only absorb light of a specific wavelength, and CO2 usually only absorbs light of a wavelength of 4.2 µm. An infrared light source with a filter provides energy to the gas quickly and continuously with pulses of light of precise wavelength. This results in rapid heating and cooling of the gas sample, which in turn causes thermal expansion and contraction.

The resulting sound can be recorded and evaluated using a microphone and used to calculate the CO2 content of the gas. The higher the CO2 concentration, the stronger the acoustic signal. Compared with the NDIR-CO2 sensor, the use of a highly sensitive MEMS microphone as a detector enables significant miniaturization.

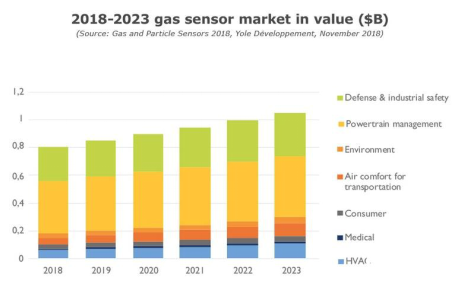

CO2 sensors are essential in many applications

Considering the needs of a large number of applications, it is not surprising that market analysts expect the double-digit annual growth rate of the CO2 sensor market. According to the "Gas and Particulate Matter Sensor-2018 Edition" report released by Yole, the gas sensor market size will reach $ 1 billion by 2022. CO2 sensors can be used to monitor indoor air to ensure better ventilation in homes, schools, offices, and commercial buildings, thereby increasing people's attention and productivity. Smaller sensors are also suitable for living areas and corresponding Internet of Things (IoT) devices such as digital assistants, smoke detectors, routers, air purifiers, and air-conditioning systems. They can even be installed in laptops or displays.

Gas Sensor Market Scale from 2018 to 2023

Pattern recognition can be used to determine the number of people in a room and the level of people's daily activities. This information can provide better air-conditioning decisions for smart buildings. In HVAC systems, CO2 sensors help them reduce electricity consumption by up to 50%, which means energy savings of 20% to 30% for the entire building.

This is because in ordinary systems, the air circulation is a constant fresh air input (for example, during working hours) in a timer mode; while management based on real CO2 measurement will adjust the fresh air supply according to the actual situation of the room. Therefore, the daily working cycle of the HVAC system is greatly shortened, and the energy saving effect is obvious.

In fact, there are many other applications of CO2 sensors, such as vehicle CO2 monitoring, which can adjust the driving position or the air quality in the entire vehicle. In agriculture, CO2 sensors can be used to control the CO2 concentration in the greenhouse to achieve higher yields and save costs. The CO2 sensor can also be used for medical applications such as a CO2 detector (capnometry); the CO2 detector is a method for measuring the CO2 content exhaled by a patient in real time, and is particularly effective in the field of anesthesia.

Industrial cases include detecting CO2 leaks near CO2 sources such as dry ice reservoirs, storage tanks, and underground sources. Smart cities can also link CO2 emission sources with vehicle density for traffic management.

Advantages of Infineon's PAS CO2 sensor solution

Infineon's newly launched Xensiv PAS CO2 sensor in 2019 uses an IM69D130 Xensiv MEMS microphone with a signal-to-noise ratio of 69 dB. The sensor is designed for scenarios with low self-noise, wide dynamic range, low distortion, and high acoustic overload points.

Thanks to the above advantages of IM69D130, the gas sensor can measure the slightest pressure fluctuations, so even a small amount of gas is sufficient to accurately determine the gas concentration. Therefore, the sampling chamber can also be designed very small. Compared with traditional CO2 sensors with the same performance (true CO2 measurement), the size of the new sensor is reduced by more than 75%. The integrated microcontroller converts the MEMS microphone output signal into a ppm reading, which can be obtained through three serial I2C, UART, or PWM interfaces. Direct ppm readings, surface mount, and simple design make it simple and fast to integrate digitally with flexible production. All internal components are developed and designed to Infineon's high quality standards.

The sensor is very rugged, with a measurement range of 0 ppm to 10,000 ppm and a measurement accuracy of up to 5000 ppm (± 3% of reading or ± 30 ppm of accuracy). Its operating temperature range is 0 ° C to 50 ° C and relative humidity is 0% to 85% (non-condensing). The drift value is less than 1% per year (active self-calibration). The design life of the CO2 sensor in pulse mode is 10 years. Xensiv PAS CO2 has these excellent properties, making it an ideal choice for demand-oriented ventilation control in smart buildings and indoor air quality control in smart home applications.

Xensiv PAS CO2 sensor typical application

Infineon is planning to introduce several variants of the sensor to meet special needs in various applications, such as low power consumption in battery-powered applications, smaller size, lower cost for portable devices, and extremely demanding industrial applications Need to be more reliable. The development of other gas sensors is also planned by Infineon.

CO2 sensor technology today

At present, non-dispersive infrared (NDIR) sensors are widely used, especially in the field of intelligent buildings. However, because NDIR sensors are relatively large and expensive, they can only be used in limited areas. This sensor consists of an infrared light source, a sampling chamber, a filter, and a reference and absorption infrared detector, which can provide true and accurate CO2 measurement. However, except for purely aesthetic reasons, NDIR sensors are not suitable for installation in mobile devices, thermostats, and other smart home components in life. The main reasons are the higher cost and lower integration capabilities caused by their size.

There is currently no similar solution on the market-both true and accurate CO2 measurement and cost-effectiveness. Although so-called eCO2 sensors can be used to detect various types of indoor pollutants, they are not a good substitute for NDIR sensors. The eCO2 sensor cannot complete the actual measurement. It uses an algorithm to calculate the equivalent CO2 value. The calculation assumes that the CO2 in the area is mainly generated by the personnel present. Therefore, eCO2 only provides estimates based on many assumptions. And the adjustment of indoor air quality based on this eCO2 value is only done based on potentially inaccurate information.

This situation can cause the air conditioning system to consume unnecessary energy, or it can't ventilate properly when air conditioning is needed. As a result, it is likely that the air quality cannot be effectively improved, and users will lose confidence in using this eCO2 sensor product.

Challenges in developing this sensor

Infineon CO2 sensors integrate photoacoustic transducers, detectors, infrared light sources and filters on a single printed circuit board. The sensor has a small microcontroller for on-board signal processing, complex algorithms, and a MOSFET for driving infrared light sources. The modulated infrared light source will radiate into the mixed gas in the sampling chamber. After absorbing infrared light, CO2 will heat up and increase the pressure in the sampling chamber. The pressure change can be measured by a MEMS microphone.

Infineon's compact Xensiv PAS CO2 sensor

During the development of the PAS-CO2 sensor, the main challenge was to maximize the performance of the microphone and minimize system noise; that is, isolate the MEMS detector from external noise, so that only the CO2 molecules from the cavity were detected. Pressure changes. Infineon modeled the response of the MEMS microphone before manufacturing the prototype device to verify the modeling results.

If you want to know more, our website has product specifications for the FPGAs, you can go to ALLICDATA ELECTRONICS LIMITED to get more information