What sensor technologies are used in automotive systems?

Automotive designers are constantly demanding devices that offer higher performance and flexibility than traditional position sensing technology. And these devices need to be versatile enough to accommodate a wide variety of applications. This requirement requires the integration of various optimal design elements included in traditional contact sensor technology and non-contact sensor technology in the device.

As more and more electronics and control systems are used in today's cars, engineers are facing increasing challenges in integrating these electronics into cars. This is especially true for sensors and other feedback (parametric) circuits that are used to ensure the safety of cars, reduce fuel consumption, and reduce emissions.

In order to be consistent with processors that handle higher speeds and I / O capabilities, electronic system designers are always faced with various challenges in improving system resolution and signal quality. For any sensing technology used in today's automotive environment, mechanical flexibility, environmental stability, and signal integrity are key design characteristics.

One of the requirements for electronic devices is the operating temperature range they can withstand. Temperatures range from a cold ambient temperature of -40 degrees Celsius to over +150 degrees Celsius in the engine compartment. Sensors and related electronics are facing the extreme temperatures that current materials can withstand. Further applications, such as variable turbochargers, continue to push the required limit temperature higher, which may exceed +180 degrees. This requires sensor designers to develop materials and packages that meet these needs.

At the same time, the sensors must be able to accept the various mechanical configurations required by the overall system. Traditional sensing devices like potentiometers and Hall-effect devices (technology) can be packaged in linear or ring packages. Both of the above technologies have their own advantages—the potentiometer has lower cost, mature technology, and is flexible in mechanical structure, while the Hall-effect device has less wear and good signal quality. Which one to choose depends on the application requirements Come on. More advanced technologies, such as inductive sensors, take advantage of the two types of sensors described above, enabling more robust sensing systems.

Potentiometer technology has high design flexibility for linear or ring applications. Depending on the design characteristics of the potentiometer, it provides an output signal that is proportional to the input voltage. However, this technique is somewhat limited by the characteristics of its analog output signal. Although this signal can be converted into a digital format, this conversion requires additional electronics, increasing the cost of the sensor. Moreover, the converted signal is not yet a true high-resolution digital format. As more and more high-speed networks and communication buses are used in automobiles, the need to arrange an AD converter for each potentiometer can be a disadvantage. The potentiometer is also a contact sensing technology that is prone to wear due to long-term work and vibration. When the wear of the potentiometer becomes obvious, it can cause excessive noise in the signal. This becomes a problem in the direct feedback control loop.

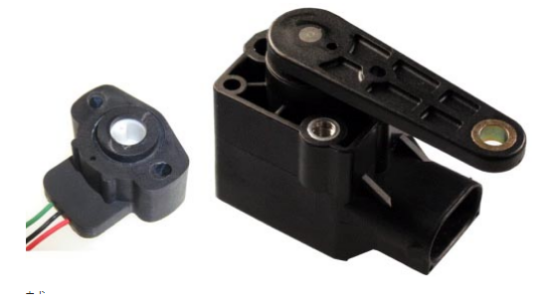

Figure 1: Traditional sensing technologies including potentiometers and Hall-effect devices.

Hall-effect sensors usually generate an analog signal. The device communicates with the automotive system by an ASIC. The ASIC also directly converts analog signals into digital signals. Because Hall technology measures changes in Gaussian magnetic flux, a very precise support system is needed to maintain its integrity. This has limited the mechanical packaging flexibility of such devices to some extent. Such a carrying system also increases the cost of the sensor to some extent. On the plus side, Hall-effect sensors are non-contact technology, so they don't degrade performance due to wear like potentiometers. Generally, to control the Gaussian magnetic field that affects Hall-effect sensors, such sensors have a relatively short moving distance. In general, Hall-effect sensors are designed for a rotation angle of less than 180 degrees or a linear motion distance of less than 25 mm.

Recent advances in the development of new inductive sensing technologies have taken advantage of both potentiometer and Hall effect technologies. The device contains a non-contact sensing system consisting of two printed circuit boards, the core of which is signal generation and sensing. The device, called Autopad, creates an inductive coupling between two circuit boards and is measured and converted by the on-board ASIC.

Unlike the Hall sensor, the Autopad sensor allows for misalignment in the X, Y, and Z axes, so a strict loading system is not required. In addition, the ASIC makes it a true digital sensor that can generate 12-bit PWM signals that can communicate directly with high-speed controllers. This signal can also be converted back to analog format if required. OPTEK's Autopad can also be implemented with a variety of physical structures, including rotating and linear structures. Rotary design can be used for systems with angular misalignment of up to 360 degrees. The linear sensor allows a misalignment of 20 to 200 mm or even more.

As the automotive industry evolves, design engineers continue to demand devices with higher performance and flexibility. Despite the advantages of traditional sensing technology, the development of inductive sensing technology has provided solutions to meet the various technical challenges and requirements of today's demanding automotive electronics. The design flexibility of this sensing technology makes it a reliable and more cost-effective solution for many automotive applications.

If you want to know more, our website has product specifications for Sensor, you can go to ALLICDATA ELECTRONICS LIMITED to get more information