What are the operating modes of Hall effect sensor switches?

There are three main types of work:

Bipolar Hall Switch: It requires the South and North poles to be higher than the specified amplitude at the same time to change the state. It is also called a latching switch.

Unipolar Forward Hall Switch: Requires one pole. Change state (low or high) based on the forward flux density being greater than a certain amplitude or less than the minimum (usually no magnetic field).

Unipolar Negative Hall Switch: One pole is required. Change the state (high or low) based on the magnitude of the negative energy density being greater than a certain value or less than the minimum value (ie no magnetic field).

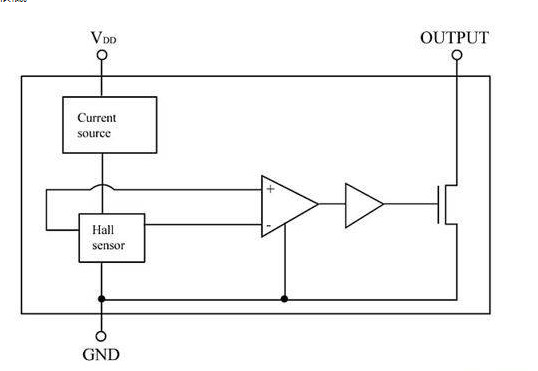

The magnetic field of the Hall plate determines the output state. The signal from the Hall-effect detector is detected, amplified, and then used to control the solid-state switching elements at the output. Connections to external logic and control components such as CMOS or TTL circuits are standard connections with external pull-up resistors. For mass production reasons, integrated Hall-effect devices (Figure 1) are usually very low cost.

Figure 1: Simplified schematic of an integrated Hall-effect device.

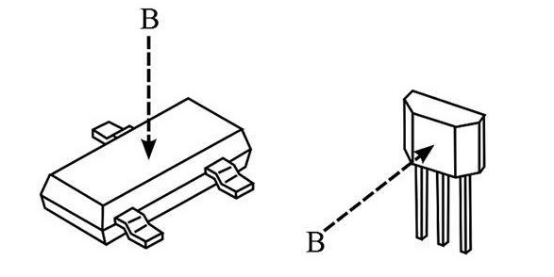

The most commonly used package types are surface mount or compatible printed circuit board lead types (Figure 2). The positive and negative magnetic field directions associated with the sensor package are defined in the manufacturer's specification.

Figure 2: Hall Effect Sensor Package Type.

To make these devices more useful in your application, keep in mind:

● Select instrument-grade devices when accurate magnetic field readings are required. Proximity detection (angle or linear) is best with integrated "switches".

● Understand important parameters such as magnetic field amplitude, AC or DC magnetic field, AC frequency, temperature range, and external noise (magnetic or electrical noise)

● Choose more robust packages whenever possible

● If you plan to use a permanent magnet, ask the magnet manufacturer for help.

Hall effect sensor history

Ever since Dr. Edwin H. Hall's experiment with a piece of gold foil in 1879, this knowledge of Hall effect has been widely spread. Although the development of modern sensors took a lot of time and energy from scientists and engineers around the world, Hawking's development has played a role in attracting a lot of attention. Choosing the right material is part of the cause of the delay. Before the mid-1950s, bismuth was the best practical material for sensor development. Although still not ideal, bismuth can provide sufficient Hall voltage and stability, and it can be used as a sensor in equipment such as electromagnetic field controllers.

Material science finally ushered in a breakthrough in the 1940s, when III-V semiconductors were the main research subject of the Soviet Union. Scientists at the German company Siemens first realized that the properties of these newly discovered compounds can make excellent Hall-effect devices (Hall generators).

This type of semiconductor has the high carrier mobility and high resistivity required for Hall-effect applications, and it has excellent stability under variable temperature conditions. By the late 1950s, researchers in Ohio, USA, had discovered the unique properties of indium arsenide and indium antimonide, and as a result, many companies producing products based on the Hall effect were born. As an instrument-level sensor, the performance of indium arsenide devices in terms of stability, low noise, and minimum temperature system has not been surpassed by other materials.

For many years, integrated circuit manufacturers have been committed to providing silicon Hall-effect devices to the market. Their high-volume production facilities and the ability to add other circuits to the sensors offer hope for low-cost, highly versatile devices. By the late 1970s, silicon Hall-effect switches had made considerable progress. The addition of Schmitt triggers and output transistors has brought a very influential device to the industry, which can provide large output changes related to the presence or absence of magnetic fields. However, there are still problems with obtaining accurate and repeatable results. Measurement results are often affected by high temperature coefficients and variable switch calibration. It wasn't until the 1980s that modern calibration and compensation circuits enabled today's integrated sensors to reach fairly high levels of performance.

If you want to know more, our website has product specifications for sensor switches, you can go to ALLICDATA ELECTRONICS LIMITED to get more information