What about the iW220l and iW2202 digital controllers based on pulse train patent technology?

Traditional analog control techniques include frequency (PFM) and pulse width (PWM) control. With the promotion and application of various low-cost microprocessor chips such as single-chip microcomputers, more and more powerful functions have been played in the core control and protection of weak current, and the microprocessor is used in conjunction with the traditional analog control chip on the PCB Embedded digital solution thinking. It is a pity that the circuit is too complicated, and it is necessary to program, etc., which is troublesome, and the total cost is still high. As a result, general designers have to look forward to digital excitement and continue to use cheap and non-programming analog chips for product design.

1. Introduction to iW2202

iWan has independently developed a "pulse Train patented technology". The core of the patented technology is to use a power pulse generator (for strong current control) and a detection pulse generator (for weak current digital processing).

The iW2202 of iWatt Company samples the binary error signal for each cycle of Pulse Train. The iW2202's own optimization algorithm logic is used to calculate the optimal quantization of the pulse train until the digital feedback setting value is met. Use iW2202 without additional programming, you can get the effect of digital control. Among them, iW22202 digital control connotation, including: "power cycle", "sensing cycle", "intelligent jump cycle" and other numerical control modes.

(1) The "power cycle" conduction time is 4 times the "sensing cycle" conduction time.

(2) The "power cycle" pulse current is 4 times the "sensing cycle" pulse current.

(3) The output energy of the "power cycle" is 16 times the output energy of the "sensing cycle".

(4) When the system output is higher than the preset fixed value, increase the "sensing cycle" pulse, and reduce the "power cycle" pulse train output, reduce the system output, so that it quickly returns to the preset calibration value. The reaction rate is fast and not comparable to general analog IC.

(5) When the system output is lower than the preset fixed value, reduce the sensing period pulse and increase the output of the power period pulse train to increase the output of the system so that it can quickly return to the preset calibration value. The reaction rate is abnormal. Much better than general analog IC.

(6) When the light load or no load, the iW2202 internal system automatically switches to the "intelligent skip cycle" mode, stops sending power cycle pulses, so that the iW2202 standby power consumption is extremely small, meeting the "Energy Star" and "Blue Sky" specifications Claim

(7) The iW2202 has a "magnetic reset automatic control" function, that is, when the flyback primary current drops to zero, the output pulse train is allowed to excite the power switch, so that there is a "magnetic reset" after each pulse, thereby avoiding The magnetic working point is offset.

(8) When the power switch is turned on, the current peak limit of the primary winding can be set to maintain the constant current working state of the primary coil. As a result of this optimization, in the input voltage range of AC 85 ~ 270V, have a higher electrical efficiency.

(9) iW2201 is an AC / AC chip without APFC. The iW2202 is an AC / DC chip with APFC function. Some of the traditional Boost analog system's out-of-control causes the APFC output voltage to be high, even exceeding 1kV, which is extremely harmful to high-voltage electrolytic capacitors. The DC bus voltage of iW2202 is lower than DC 400V, which effectively reduces the voltage stress, can greatly provide reliability, and reduces the application cost.

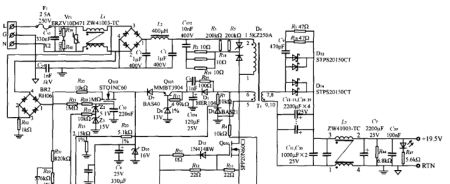

(10) In particular, the readers should be reminded that the iW2202 can also work in the APFC working condition without high-voltage electrolytic capacitors. The application of iW2202 can get a high PF and a very low THD. as shown in picture 2.

As we all know: electrolytic capacitors have a large volume, which has become an obstacle to the development of products "thin, small, and light "! The price of electrolytic capacitors is more expensive, which has become the focus of reducing product costs! The storage life and working life of electrolytic capacitors are extremely limited, and have become a revolutionary object for improving the reliability of electronic products! Therefore, the application of iW2202 switching power supply can maintain high efficiency, high power factor, low harmonic coefficient and other comprehensive parameters without using high-voltage electrolytic capacitors ! This is absolutely great news for electronic designers.

If you want to know more, our website has product specifications for controllers, you can go to ALLICDATA ELECTRONICS LIMITED to get more information