What are the applications of high-precision humidity measurement sensor modules in monitoring battery management systems?

In the design process of ensuring the safety of the battery system, in addition to the characteristics of the battery cell, the design of the battery module, the structure of the battery pack, and the design of the exhaust gas, the battery management system has the most main control. Since the battery pack is composed of multiple batteries connected in series, its effective performance is based on the weakest single battery. The difference in battery capacity is due to chemical imbalances in the manufacturing process, location (heat change) in the battery pack, and changes related to usage or life.

The difference between battery voltages indicates an imbalance in the battery at the system level. The reason for this difference is still under study. It is very important to fully understand this, because it affects the duration of the battery pack in terms of power output, as well as the usable life of each cell and the life of the battery pack.

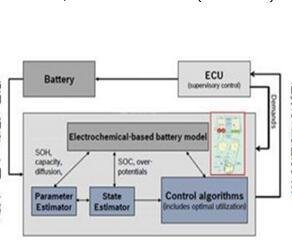

Starting from the nickel-metal hydride battery, due to its own characteristics, the battery needs a battery management system to manage it. It is also one of the elements in the overall architecture of new energy vehicles. Overall, the main purpose of the battery management system is to measure the battery status and extend the battery life. The common function modules of the battery management system can be divided into measurement function, state calculation function, system auxiliary function and communication and diagnosis according to the preliminary division.

Temperature is of great significance to the parameters of the battery, which is also a source of controversy here. When designing the battery and the module, the temperature difference between the inside and outside of the battery, the welding of the battery lugs and busbars, the temperature difference between the battery in the module and the maximum temperature difference in the battery pack are all parameters that have been included in the design of the entire battery pack. Early control was carried out. The location of the BMS in the design of the temperature sensor, and how many temperature points are placed and the temperature points finally collected to characterize the operation of the entire battery pack are not the scope of BMS management. The accuracy of temperature detection is also very particular. For example, at -40 degrees, the detection accuracy does not need to be particularly high, because the use of the battery system itself requires heating, and the area of -10 degrees to 10 degrees has a significant impact on battery performance There are also 40-degree high temperature proximity points, these are areas that need to be focused on. In the design process, you can use the values of the pull-up resistor, filter resistor, and temperature sensor to perform Monte Carlo analysis.

The battery packs are often only connected in parallel at the level of the monomer (the most extreme is the 75 parallels of Tesla's small batteries). The batteries in the battery pack are connected in series to provide power to the vehicle, so generally only one current needs to be measured. . The current measurement method is mainly divided into two kinds of intelligent shunt or Hall current sensor. Because the current value that the battery system needs to handle is often large instantaneously, such as the discharge current required for vehicle acceleration and the charge current during energy recovery, the range and output current (discharge) and input current (charge) of the battery pack are evaluated and measured. Accuracy, this is a job that requires careful inspection. Current is the main reason for the temperature change of the monomer, and the internal resistance and chemical heating together form the battery heating; when the current changes, it will also cause the voltage change. Together with time, these three items are essential elements for calculating the battery status. .

There are usually multiple relays in the battery pack. The battery management system must at least complete the drive supply and status detection of the relays. The relay control is often confirmed after coordination with the vehicle controller, and the collision signal output by the airbag controller is generally The relay controller disconnects the direct hook. The relays in the battery pack generally have main positive, main negative, precharge relays and charging relays, and there is a separate power distribution box outside the battery pack to provide more detailed protection for the entire current distribution. For the relay control of the battery pack, the closed and open states and the order of the switches are very important.

As mentioned above, the chemical performance of the battery is greatly affected by the temperature of the environment. In order to ensure the service life of the battery, the battery must be operated within a reasonable temperature range, and the vehicle controller can obtain its ability according to different temperatures. Maximum power output and input. For the temperature control of the battery system, CFD simulation analysis is mainly used. As the temperature sensor unit mentioned above, how to use the fewest sensors to effectively monitor the temperature distribution of the entire battery pack, and feedback the monitoring information to the battery management system and The entire battery temperature management system.

Finally, we recommend a high-quality temperature and humidity sensor, high-precision humidity measurement sensor module-HTW-211, HTW-211 is an accurate and reliable humidity measurement sensor based on HumiChip. The humidity output of the sensor has been temperature compensated and is a linear voltage, which can be directly connected to the microcomputer with ADC input. Specially designed molded packaging and coating materials can ensure resistance and reliability even in harsh environments.

If you want to know more, our website has product specifications for battery management systems, you can go to ALLICDATA ELECTRONICS LIMITED to get more information