How to design the power module of LED display?

1 Introduction

Led display screen is a new type of information display media that is rapidly developing. With the continuous development of my country's economy, it has been widely used in public places such as stations, hotels, banks, and hospitals. The power supply of the display screen is an important part of it, which is mainly used to provide the necessary working current to the LED of the display screen to ensure the normal display of the screen body. For the sake of simplicity, a power supply scheme with a small power supply and 3 to 4 display driver boards is usually adopted. In this way, a large-area display screen needs to be equipped with many power modules, such as a 2m × 1.5m screen body, and it is necessary to provide 24 5V / 20A module power supplies. This design has the following disadvantages.

1) Complex wiring Each power supply needs to be equipped with an AC input line and a DC output line separately.

2) Poor power supply redundancy In most cases, the display content of the screen is text, animation, and pictures. The current consumed by each display driver board is different. Some power supply modules may be overloaded, while others are empty. In addition, if a power supply fails, a part of the screen will be blank.

3) Poor power overload capacity, low utilization rate The current consumed by the screen during operation varies with the content, color, and brightness of the screen. Most of the time, the current is small, and the large area and high brightness screen consumes large current, but continues short time. Considering that the LED is driven by constant current, as long as the driver board can work normally, the power supply voltage can be lowered. The power supply preferably has a current-limiting characteristic in the shape of a drag, rather than the current-limiting characteristic of the steeper shape, to ensure a better overload capacity and a higher utilization rate.

Considering the above points, the new power supply scheme is proposed as follows:

1) Centralized power supply, using n + 1 redundancy scheme.

2) The power module is designed with proper output current, and the module can share current. Ensure that the screen assembly process is easy to achieve n + 1 redundancy.

3) The power supply module has the current-limiting characteristics of the drag shape to ensure a better overload capacity and a higher utilization rate.

4) The power module has a flat shape, natural heat dissipation, easy to install on the screen body, and use the screen body to dissipate heat.

5) The power module has APFC to reduce the interference to the power grid and adapt to the fluctuation of the power grid.

2 Circuit design

The centralized power supply scheme can avoid the shortcomings of decentralized power supply, but it requires higher reliability of the power supply. Otherwise, once the power supply fails, it will cause a black screen instead of a partial black screen. The most positive way to improve the reliability of the power supply is to improve the conversion efficiency and reduce the amount of heat generated, and at the same time select high-reliability circuits and devices.

2. 1 AC / DC circuit design

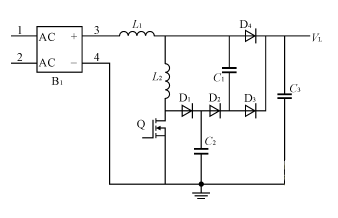

The traditional AC / DC full-wave rectifier circuit uses a rectifier + capacitor filter circuit. This circuit is a combination of a non-linear device and an energy storage element. The waveform of the input AC voltage is sinusoidal, but the waveform of the input current is severely distorted and shows a pulse shape. The resulting harmonic currents have a harmful effect on the power grid and cause the input power factor of the power supply to drop. In this design, the active power factor correction circuit (APFC) is used in the rectifier circuit to avoid the above-mentioned shortcomings. The circuit is shown in Figure 1.

Figure 1 PFC lossless absorption main circuit

Unlike the typical PFC main circuit, this circuit uses a lossless absorption buffer network. The network reduces the switching loss of the switch tube, improves its stability, and enhances its service life. It uses a group of passive components to make the switch tube achieve zero current turn-on and zero voltage turn-off, improve the working efficiency of the power supply, and reduce the production cost relative to other resonant soft switching circuits.

If you want to know more, our website has product specifications for power module, you can go to ALLICDATA ELECTRONICS LIMITED to get more information