Do you know laser displacement sensing technology?

At present, the major industrial countries in the world are upgrading their industries, and the upgrading of modern industries is inseparable from laser technology. In addition to playing a huge role in production and processing, laser technology also has important applications in accurate real-time measurement, including the size of electronic products, the curvature of transparent components, the vibration spectrum of large three-dimensional objects such as automobiles and airplanes, bearing concentricity, eccentricity, and Vibration provides accurate measurement, which greatly improves product output and production efficiency.

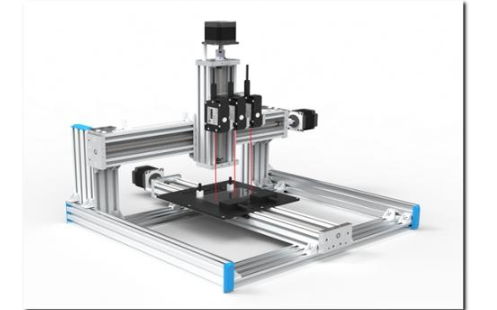

Schematic diagram of mobile phone glass curvature detection using laser measurement technology

To realize the specific application of laser accurate real-time measurement in the industrial field, it is inseparable from the research and development and promotion of various laser sensors. As we all know, modern manufacturing is already a sensor-driven world. In almost all manufacturing processes, accurate real-time measurement relies heavily on sensors. After the introduction of optical technology, the sensor is developing in a faster, more accurate, and more reliable direction. Compared with traditional measurement methods, optical measurement sensors, especially laser measurement sensors, are widely used in industry due to their non-contact and rapid measurement capabilities. The most typical application example is the high-precision laser displacement sensor.

Current status of laser displacement sensor market

Laser displacement sensors are often used to measure physical quantities such as length, distance, vibration, speed, and orientation, and can also be used for flaw detection and atmospheric pollutant monitoring. The measurement of the thickness change of the thin metal sheet (thin plate) by the laser displacement sensor can help find wrinkles, small holes or overlaps, and avoid machine failure; and identify the position of small parts, monitor the presence of parts on the conveyor belt, and the position of the manipulator (tool center Position) control and other aspects can ensure the efficient operation of equipment and production lines; in the filling product line, the extension program of the laser beam reflection surface can be used to accurately identify whether the filling product is qualified, and the quantity is monitored. At the same time, the filling quality can be guaranteed. In addition, laser displacement sensors have unparalleled advantages in absolute distance measurement, relative displacement measurement, remote vibration measurement or vibration spectrum measurement, profile detection, thickness measurement, curvature measurement, and thickness measurement of transparent objects.

According to data, the domestic general-purpose laser displacement sensor market has reached 12 billion and maintained a growth rate of 20% every year. However, 99.87% of the domestic market is occupied by foreign manufacturers, mostly in developed countries such as Europe, America and Japan, such as General Electric, Bonner, German Sigg, Japanese Keyence and so on. These companies continue to maintain their market position through technological innovation and product upgrades. Although my country's industrial automation system integrators have a cognition rate of more than 95% of this device, the actual usage rate is less than 10% due to high price and difficulty in adaptation.

Compared with advanced foreign enterprises, my country's sensor technology lags behind 10 years in scientific research and development, and 15 years behind in production technology. However, in recent years, China has successively formulated policies that are conducive to the development of the sensor industry, and established a number of state key laboratories for sensor technology and robotics. At the same time, more than a thousand companies have chosen to engage in sensor production and research and development, and the process of domestic sensor industrialization follows accelerate. At present, domestic companies engaged in laser sensors are mostly small and medium-sized enterprises, mainly in the Yangtze River Delta region, with a small number of large enterprises. Representative companies include Yuyao Sunny Optics, Beijing Chuangxiang Intelligent Control, , as well as start-up companies that adopt advanced integrated optical technology.

Laser displacement sensor introduction

At present, there are many technologies that can achieve accurate optical displacement measurement. Industrialized laser displacement sensors generally use two methods: laser triangulation and laser echo analysis. In addition, color confocal and interferometric measurement principles can be used for accurate displacement. measuring. In addition, laser displacement sensors are also used for non-contact vibration measurement. However, for specific measurement conditions and measurement requirements, the above methods have their own defects.

For laser displacement sensors, the laser triangulation method is suitable for high-precision, short-distance measurement, and the laser echo analysis method is used for long-distance measurement. In the current application of industrial robots, triangulation is usually used. The highest linearity of this method can reach 1um, and the resolution can reach the level of 0.1um.

Laser triangulation is a single-point or multi-dimensional distance measurement obtained by angle calculation. The visible red laser beam is directed to the surface of the measured object through the lens, and the laser reflected by the object passes through the receiver lens and is received by the internal CCD linear camera. According to different distances, the CCD linear camera can "see" this light at different angles. point. Based on this angle and the known distance between the laser and the camera, the digital signal processor can calculate the distance between the sensor and the measured object.

The law of echo analysis is that a laser transmitter emits one million laser pulses per second to the detection object and returns to the receiver. The processor calculates the time required for the laser pulse to meet the detection object and return to the receiver to calculate Distance value. The output value is the average output of thousands of measurement results, which is measured by the so-called pulse time method. The farthest detection distance can reach 250m.

In terms of precise vibration measurement, the commonly used laser Doppler vibrometer (LDV) works on the basis of optical interference, through the superposition of two coherent beams I1 and I2 for measurement. The superimposed light intensity is not simply the sum of the two light intensities, but also includes a coherent modulation term. The modulation term is related to the path length between the two beams.

Although laser triangulation is relatively simple and reliable to measure displacement, its disadvantage is that the measurement accuracy decreases as the measurement distance and range increase, so the measurement range is limited. In addition, a certain open space is required to meet the measurement requirements of the triangulation method, so it cannot be used in deep trenches or deep holes. The laser echo analysis method is suitable for long-distance detection, but the measurement accuracy is lower than that of the laser triangulation method. In terms of vibration measurement applications, the detection capabilities (frequency range/vibration range/precision) of the first two displacement/distance measurement technologies are relatively limited. Although LDV can perform very accurate vibration measurement and instantaneous displacement measurement, it lacks the ability to measure absolute displacement or distance, and the cost is quite high.

This article is from Allicdata Electronics Limited which offer electronic components, semiconductors, antennas, capacitors, connectors, diodes, transistors, IC,resistors. For more product information, please go to the website to get it.