What are the detection methods of the sensor?

On shot

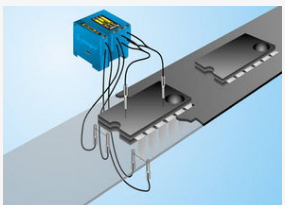

The transmitter and receiver of the radiation detection method are installed facing each other, and the light of the transmitter is directed at the receiver. When the measured object blocks the beam, the sensor output changes to indicate that the measured object is detected.

The through-beam type is one of the earliest photoelectric detection modes. Before the emergence of modulated light, the alignment of the transmitter and receiver was a big problem. Today, for photosensors that use high-energy modulated light, it is easy to align the transmitter and receiver.

Beam alignment-on-beam

The alignment of the light path allows the maximum amount of transmitted light to reach the receiver, and the emitted light should be located in the center of the receiving area.

When the transmitter is visible light, in order to facilitate the alignment of the light path, place a light-colored calibration object directly in front of the receiver lens and adjust the position of the transmitter by observing the light spot on the calibration object. Remove the calibration object, observe the excessive gain indicator on the sensor, and fine-tune the position of the transmitter and receiver to achieve the best alignment position.

Detection distance-through-beam

The detection distance is a very important parameter of the sensor. For a through-beam sensor, this parameter refers to the maximum distance between the transmitter and receiver of the sensor. The effective light beam refers to the active part of all the emitted light beams. In order to reliably detect an object, this part of the light must be completely blocked. The effective beam of the through-beam detection mode can be compared to a transmitter

A rod of the lens (or ultrasonic transmitter) and the receiver lens (or transmitter). If the lens sizes of the transmitter and receiver are not the same, the rod will become tapered. The effective beam is not the same as the beam emitted by the transmitter or the receivable area of the receiver.

For the through-beam photoelectric sensor, when detecting small parts or performing precise positioning, the effective beam may be too large to perform reliable detection. In this case, an optical slit can be added to the sensor to reduce the effective beam size. (Note: When selecting light-slit materials, pay attention to some non-metallic materials that may be penetrated by high-energy modulated light).

Installing a light slit will reduce the energy of the light passing through the lens (the smaller the light slit, the less light will pass). For example: After a lens with a diameter of 20mm is installed with a light slit with a 5mm hole, the energy of the light passing through this hole is only the original (1/4) 2 or 1 / 16th. Seam, the energy of light will be doubled.

Compared with the circular aperture slit of the same size, the rectangular light slit has a larger area for the lens to receive light. Therefore, if the direction of the object passing through the beam is constant, a rectangular light slit (such as edge detection) is preferred. If the direction of the small object through the beam is not fixed, a circular light slit is preferred.

If the object to be measured is always very close to the transmitter or receiver when passing, only one light slit is required. The effective beam size is the size of the hole in the light slit at the end with the light slit, and the size of the lens at the end without the light slit, which is tapered.

When using a through-beam sensor to detect small objects, when using a through-beam sensor to detect small objects, on the one hand, it must ensure that the size of the effective beam must be smaller than the minimum size of the measured object, while keeping the lens as large as possible. Area to ensure sufficient detection distance. A simple method is to use an optical fiber. The light exit holes of this optical fiber detection head have a variety of shapes and sizes to suit different test objects.

Some high-energy modulated through-beam sensors, when used in close range, sometimes cause a surge in light energy around the object being measured, causing the sensor to malfunction. This is one of the reasons why the size of the measured object must be larger than the effective beam size.

For a through-beam ultrasonic sensor, its waveform can be determined by using a sound wave guiding device. This device is mounted on the receiver's transmitter (sometimes also on the transmitter). After installing this device, the receiver will respond weakly to the sound waves coming from the side, so it can reliably detect small objects.

If you want to know more, our website has product specifications for sensor, you can go to ALLICDATA ELECTRONICS LIMITED to get more information