What is an AC Link Closed Loop Current Sensor?

At present, most manufacturers use closed-loop sensors on the AC side, because the output of the AC-side current sensor is generally used for software control. If the accuracy is too low, it will affect the detection and control of some key quantities. For example, the detection and extraction of DC components. Although the acceptance value of DC components is different in each country, it needs to be controlled at 0.5% or even 0.25% of the nominal output current. Therefore, only closed-loop sensors can meet the requirements of high accuracy.

At present, with the high integration of photovoltaic modules, the improvement of new device processes, and advances in technology developed by inverter manufacturers, the power of individual modules of photovoltaic inverters has become larger and larger, and the power density has become higher and higher. For current sensors, The choice also raises higher requirements. In addition to having conventional electrical performance, it also requires:

a) Small size, high insulation and voltage resistance, high integration, easy to automate production

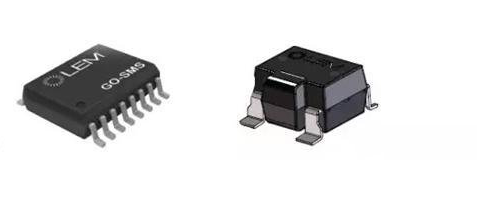

When the layout space for current measurement on the Print Circuit Board is relatively small, it is ideal to use a chip-type current measurement scheme. Integrate the primary conductor and directly surface mount the device to the printed circuit board, thereby reducing manufacturing costs while avoiding confusing various soldering processes. LEM's latest GO-SMS (bottom left) / HMSR-SMS (bottom right) series current sensors are chip-type current sensors in SMD packages.

In addition to meeting the small size, the original secondary pin design of GO-SMS also achieved 7.5mm creepage and clearance distance, respectively. The original secondary pin design of HMSR-SMS reached 8.0mm creepage and Clearance distance. The package uses 600 CTI material to accumulate to make it have high isolation performance (test isolation voltage: 4.3kVrms / 50 Hz / 1min), among which HMSR chip-type current sensor is specially used for solar system with 1500Vdc DC input.

b) 10kA anti-surge capability

At present, in the design of inverter manufacturers, there is generally a risk of lightning surges on the lines directly connected to photovoltaic modules (PV panels) or the grid. In order to help manufacturers simplify the lightning protection design at network ports, HMSR-SMS was designed at the beginning of the design. Taking full account of the anti-surge capability of the primary side, a specially optimized primary conductor is designed. When the primary side passes the lightning surge current of 10kA 8 / 20us, the chip can still work normally without any failure.

c) Built-in overcurrent protection alarm function

GO-SMS / HMSR-SMS chip-type current sensor can be used for peak current detection. It is used to compare the true value with the set point (protection point). The protection point can be set using the built-in (factory default) or external ( (The user modifies the value), and outputs a valid low-level warning message through the dedicated OCD pin to notify the controller (DSP) of the overcurrent signal generation so that the DSP can respond quickly to protect the IGBT and other devices in the circuit.

In addition to the above features, LEM's chip-type current sensors can measure nominal AC, DC, pulse, and hybrid isolated currents, with a wide measurement range of ± 3 x Ipn and a bandwidth of 100kHz.

GO-SMS / HMSR-SMS chip-type current sensor design is based on the unique LEM open-loop Hall-effect ASIC technology of the HG2 ORION platform. It is marked with CE mark and conforms to EN50178 standard. Compared with traditional discrete technologies, it has a wider operating temperature range (-40 to + 85 ° C), better offset and gain drift, and linearity.

GO-SMS / HMSR-SMS chip-type current sensor operates through a + 5V power supply and provides a configurable reference voltage (2.5V). The gain and offset are fixed and set. The output corresponding to the rated measurement current The voltage is equal to the input or output reference voltage ± 0.625 V. It can provide a rated current detection capability of 10-30A, which is very suitable for string current detection on the DC side and input current detection of the DC / DC Boost circuit.

If you want to know more, our website has product specifications for Sensor, you can go to ALLICDATA ELECTRONICS LIMITED to get more information