What are the requirements for signal conditioning of gas detection sensors?

At present, industrial production safety, environmental pollution and other issues have attracted much attention. One of the accidents was caused by the leakage of toxic, flammable and explosive gases. Therefore, the detection, early warning and prevention of such gases are of great significance. More and more companies are devoted to the monitoring of toxic / harmful gases. This article will briefly introduce the characteristics of gas detection sensors and the excellent signal conditioning devices they provide.

Signal conditioning requirements

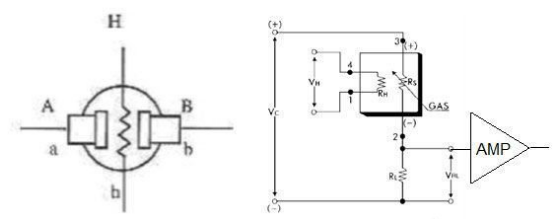

This type of sensor usually contains 4/6 pins, as shown in follow Figure: H / h is the heating stage, A / a and B / b are the two poles of the sensitive resistor, A / a is internally shorted, and B / b is internal Short circuit. VH is the heating voltage, Vc is the excitation voltage, and RL is the termination load resistance. The resistance value of the sensor can be obtained through the voltage VRL at both ends, and the gas concentration can be obtained (calculated according to the characteristic curve provided by the sensor manufacturer).

When measuring VRL, the requirements for back-end amplifiers and data converters (ADCs) are generally not high. Generally, low-cost amplifiers with high input impedance and less than 1Mhz bandwidth are selected. ADC: Low cost. Generally, the resolution of ADC integrated with single chip microcomputer (MCU) is 8 bits, and the sampling rate is 1Kbps, or the comparator is directly used as an alarm function. The adjustment of the threshold value is related to the load resistance RL.

The AD8613 is a low cost, low power amplifier with a bandwidth of 400Khz and an offset voltage of 2.2mV. It can be used as a buffer / amplifier circuit.

AD7170 is a low-power, 12-bit resolution S / D ADC with a data throughput of 125hz. It is suitable for data acquisition systems with low power consumption and general accuracy requirements.

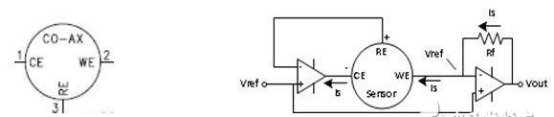

2. Electrochemical formula:

Electrochemical sensors are usually output in current mode, and the sensitivity of the signal ranges from tens of nA / ppm to hundreds of nA / ppm. The value varies depending on the type of gas. In addition, sensors from different manufacturers are slightly different. These sensors generally have 3 pins, namely working electrode (WE) / reference electrode (RE) / counter electrode (CE). The current flowing between the working electrode and the counter electrode is proportional to the gas concentration. The reference electrode has no electrode flow, it just provides a reference voltage. For different gas sensors, the reference voltage will be different. Please read the product manual carefully when designing the back-end circuit.

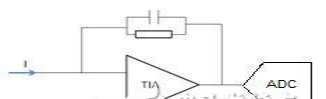

The sensor needs to use TIA (Trans Impedance Amplifier) to convert the current signal into a voltage signal, and then perform analog-to-digital conversion. Because the output current of the signal is small, a precision op amp with a small Ib (bias current "10pA) needs to be selected.

The ADA4505-1 / 2/4 are ultra-low power, rail-to-rail, zero-crossover distortion input-output amplifiers. Ib is 0.5pA, the power supply range is 1.8 ~ 5V, and the power consumption of each amplifier is 10μA, which is very suitable for this application.

AD7988-1 is a 16-bit resolution, 100Kbps sampling rate SAR type ultra-low power ADC. Power consumption is only 0.7mW at 100Kbps sampling rate.

AD7792 / 3 is a S / D ADC with 16 / 24bit resolution and low power consumption. The integrated instrumentation amplifier and its reference source are suitable for low frequency and high precision sampling systems.

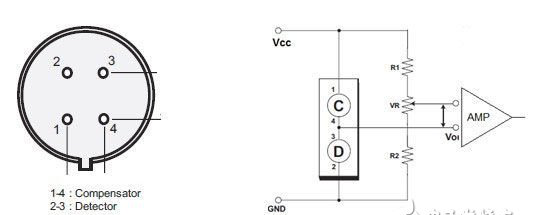

3. Catalytic combustion:

The catalytic combustion sensor is shown in follow Figure. Including detector terminal and compensation terminal. Configure the external R1 / R2 / VR to balance the bridge. Using the Wheatstone bridge principle, the induction resistor and the flammable gas in the environment burn without flame, so that the temperature changes the resistance of the induction resistor, breaks the bridge balance, and outputs a stable electrical signal. Stabilization and processing finally yielded measurements. In this kind of application, the amplifier needs to have a high common-mode rejection ratio and low offset voltage, which can be realized by an instrumentation amplifier.

The AD8420 is an instrumentation amplifier with low power consumption of 90μA, wide voltage supply range of 2.7V to 36V, and high common-mode rejection (<100dB) rail-to-rail output.

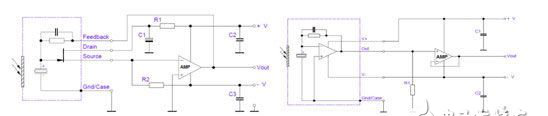

4. Infrared:

Thermal potential is an important type of infrared sensor. The sensor and its typical interface circuit are shown in follow figure. The part in the box is the sensor, which has two types of JFET and CMOS op amp integrated inside. Regarding the external need for precision operational amplifier to condition the output signal. The temperature change has a great impact on this type of sensor, and there is usually a temperature correction link.

5, PID photoionization:

The PID photoionization sensor's circuit part includes not only the signal detection circuit, but also the control of UV light power drive, fan control circuit and so on. Strictly speaking, it is a gas detector, not a sensor. Only the detection part of the signal is discussed below. After photoionization, the generated ion current is usually on the order of 0.1nA, and weak signal detection technology is required. TIA amplifiers that require ultra-low bias currents are extremely important to handle noise, as shown in follow Figure. After the signal is amplified, a high-precision, low-noise analog-to-digital converter ADC is required. Of course, there are some sensors that handle this all well and provide users with voltage signals of mV level sensitivity directly. On this basis, the user can process through a simple amplifier circuit.

AD549L: For the detection of weak current signals, it provides the industry's outstanding ultra-low bias current amplifier, Ib is only 60fA max.

The AD7190 is a 24-bit, ultra-high-precision S / D ADC. At a 4.7Hz throughput rate and a gain of 128, the noise level is only 8.5nV / sqrt Hz. It is widely used in ultra-high-precision data sampling systems.

For signal processing at the back end of gas sensors, ADI offers very competitive signal conditioning products, such as operational amplifiers, instrumentation amplifiers, data converters, etc. as described above.

Summary

The detection of toxic and harmful gases has become an important branch of environmental monitoring and chemical analysis applications. The development of its sensors is also changing with the needs of applications. At the same time, challenges have been raised for signal processing at the back end. ADI has been committed to precision signal processing, and its leading technology and signal conditioning products (amplifiers, data converters, etc.) have brought excellent performance in terms of reliability and accuracy of gas measurement, which meets this application well. Demand.

If you want to know more, our website has product specifications for the sensors, you can go to ALLICDATA ELECTRONICS LIMITED to get more information