What is a fiber Bragg grating (FBS) sensor?

The fiber Bragg grating sensor is a fiber sensor with the highest frequency and the widest range. This sensor can change the wavelength of the reflected light wave according to the change of ambient temperature and / or strain. Fiber Bragg Grating uses a holographic interference method or a phase mask method to expose a short section of light-sensitive fiber to a light wave with a periodic intensity distribution. In this way, the optical refractive index of the optical fiber will be permanently changed according to the intensity of the irradiated light wave. The periodic change of light refractive index caused by this method is called fiber Bragg grating.

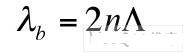

When a broad-spectrum beam is propagated to a fiber Bragg grating, each small length of fiber after the refractive index is changed will only reflect a specific wavelength of light. This wavelength is called the Bragg wavelength, as shown in the following equation ( 1) as shown in. This characteristic allows fiber Bragg gratings to reflect only light waves of a specific wavelength, while light waves of other wavelengths are propagated.

In equation (1), λb is the Bragg wavelength, n is the effective refractive index of the fiber core, and Λ is the interval length between gratings, called the grating period.

Because the Bragg wavelength is a function of the spacing length between the gratings (Λ in equation (1)), fiber Bragg gratings can be produced with different Bragg wavelengths, so that different fiber Bragg gratings can be used to reflect specific wavelengths Light waves.

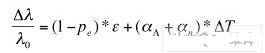

Changes in strain and temperature will affect both the effective optical refractive index n of the fiber Bragg grating and the grating period Λ, resulting in a change in the wavelength of the reflected light wave of the grating. The change of the reflected wavelength of the fiber Bragg grating with strain and temperature can be approximately expressed by the relationship in equation (2):

Where Δλ is the change in reflection wavelength and λo is the initial reflection wavelength.

The first expression before the plus sign on the right shows the effect of the change in strain on the reflected wavelength. Where pe is the strain optical sensitivity coefficient, and ε is the strain affected by the grating. The second expression after the plus sign represents the effect of temperature changes on the wavelength. Where αΛ is the thermal expansion coefficient and αn is the temperature optical sensitivity coefficient. αn embodies the influence of light refractive index due to temperature change and αΛ embodies the change of grating period caused by the same temperature change.

Because fiber Bragg gratings will be affected by both strain and temperature changes, both the two factors must be considered and analyzed separately when calculating the reflected wavelength change. When performing temperature measurements, the fiber Bragg grating must be kept completely unaffected by strain. You can use the FBG temperature sensor specially packaged for this purpose. This sensor can ensure that the properties of the fiber Bragg grating inside the package will not be coupled to any external bending, stretching, squeezing or twisting strain. In this case, the coefficient of thermal expansion αΛ of glass is usually negligible in practice; therefore, the change in the reflection wavelength due to temperature changes can be mainly determined by the temperature optical sensitivity coefficient αn of the fiber.

The fiber Bragg grating strain sensor is more complicated in a certain procedure, because temperature and strain will affect the reflection wavelength of the sensor at the same time. In order to carry out the measurement correctly, the influence of temperature on the fiber Bragg grating must be compensated during the test. To achieve this compensation, a FBG temperature sensor with good thermal contact with the FBG strain sensor can be used. After obtaining the test results, simply subtract the wavelength change measured by the FBG temperature sensor from the wavelength change measured by the FBG strain sensor to eliminate the second expression on the right side of the plus sign from equation (2), thus Doing this compensates for the effects of temperature changes in the strain test.

The process of installing the fiber Bragg grating strain sensor is similar to the process of installing the traditional electrical strain sensor, and FBG strain sensor has many different types and installation methods to choose from, including epoxy type, weldable type, bolt fixed type Embedded type.

If you want to know more, our website has product specifications for sensor, you can go to ALLICDATA ELECTRONICS LIMITED to get more information