How to design of energy-saving electric vehicle AC drive system based on boost DC-DC bidirectional converter and inverter?

Main unit circuit design

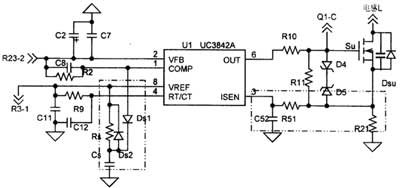

1. Switch tube Su control circuit

According to requirements, the control chip needs to have functions such as soft start, overcurrent, and undervoltage protection. The system uses UC3842A from Motorola, which is a function that can complete feedback voltage comparison, error amplification, overcurrent protection, undervoltage protection and other functions. Current tracking type PWM control integrated circuit.

The switch tube Su control circuit is shown as in Fig. 2. Its working characteristics are: ① The maximum power supply voltage Vcc = 30V, there is a 36V voltage regulator tube inside to effectively prevent damage caused by high-voltage intrusion; ② Undervoltage lockout function, the threshold of the starting voltage is 16V, the shutdown voltage is 10V, 6V The difference between startup and shutdown can effectively prevent the circuit from oscillating when working near the threshold voltage; ③ comes with a stable 5V reference voltage, output by pin 8 for external use, the output current is 20mA; ④ the output high level is 13.5 V (Vcc = 15V, when output current is 200mA), low level is 1.5V (when input current is 200mA); ⑤ High and low level rise and fall time is 100ns, current sampling signal (input from pin 3) When it is greater than 1V, the pulse width modulation latch flips, and the output pin 6 immediately drops from high level to low level. Therefore, by changing the size of the current sampling resistor, the threshold of the overcurrent protection action can be changed. ⑥ Current tracking characteristics: When the current flowing through the switch tube Su in Figure 1 increases, the sampling voltage on the sampling resistor R21 increases, and the signal entering pin 3 of UC3842A becomes correspondingly larger. At this time, it is adjusted by the internal adjustment circuit of 3842A. The duty cycle of the output pulse of pin 6 is correspondingly reduced, so that the output voltage of the DC-DC converter is reduced, and the current flowing through Su is correspondingly reduced, which plays a role in current protection.

Figure 1 switch tube Su control circuit

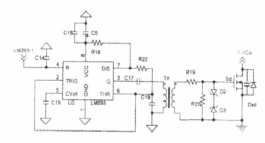

During the energy feedback, the switch tube Sd is in the working state. In order to ensure that the system energy is fully fed back, and at the same time avoid the switch tube Sd to withstand a large feedback current for a long time, the "multivibrator + high-frequency pulse transformer with a frequency of 20 kHz composed of 555 is used "To drive Sd.

Figure 2 is the drive circuit composed of "multivibrator + high frequency pulse transformer", in which the working frequency of the multivibrator composed of 555 is f = 1.43 / (R18 + 2R22) / C19. In this circuit, the detection and interlock circuit controls pin 4 of the 555 manifold. When pin 4 is high, that is, the detection circuit detects that the system should enter the energy feedback state, the multivibrator starts to output switching pulses to Sd; when pin 4 is low, the system is in electric operation, multivibration The oscillator does not output switching pulses to Sd.

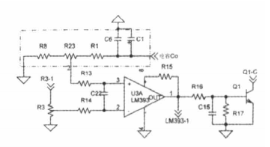

2. Detection and interlock circuit

In this system, the detection and interlock circuit has an extremely important role. First, it determines whether it is necessary to switch the circuit operating mode from the electric operating state to the energy feedback state or from the energy feedback state to the electric operation state by detecting the voltage level at the output end of the DC-DC converter; second, it needs to detect and As a result of the judgment, the drive circuits of the electric operation switch tube and the energy feedback switch tube are controlled accordingly. Figure 3 shows the detection and interlock circuit. Its working principle is as follows: First, set the reference voltage of the comparator pin 2 according to the output voltage of the DC-DC converter during normal operation, and use a resistor divider to detect the DC- The voltage at the output of the DC converter. When the system is decelerating downhill or braking, the motor is in the power generation state, then the back-EMF of the machine is greater than the output voltage of the DC-DC converter, that is, the comparison voltage detected by the resistor divider is greater than the reference voltage , Making the comparator flip, pin 1 output is high, it forces the transistor Q1 to turn on, pull down the gate signal of the switch tube Su to low level; in addition, also because the voltage divider is provided to pin 2 of UC3842A When the voltage exceeds the internal reference voltage of chip one, it immediately turns off the pulse output of UC3842A. The two safely blocked the switch tube Su. At the same time, the high level of the pin 1 of the comparator enters the pin 4 of the multivibrator, turning on the multi-resonance oscillation circuit, so that the entire system enters the energy feedback state.

3. Main circuit intelligent power module IPM

In this system, the three-phase inverter circuit has a very important role. It not only provides the power supply voltage for the squirrel-cage asynchronous motor, but also controls the frequency conversion of the motor. In the past, the inverter circuit was mainly constructed with 6 separate IGBT units. It is necessary to provide a driving circuit, an overheat protection circuit, and an overcurrent protection circuit for each IGBT unit. The matching of IGBT units makes the design of variable frequency inverter circuits quite difficult. However, with the emergence of intelligent power modules (IPM), this situation has been greatly changed, especially in recent years, IPM is gradually replacing ordinary IGBT modules.

The IPM module is a high-performance high-power device integrating the IGBT chip as the main body, integrating the chip and its gate drive, control and overcurrent, overvoltage, overheat, short circuit, undervoltage lockout and other protection and fault detection circuits. It has the advantages of compact structure, small volume, stable performance, reliable operation and moderate price. Therefore, combined with the basic requirements of the electric vehicle driving device, the IPM module PS21255-E produced by Mitsubishi was selected as the inverter circuit in this system.

In the PS21255-E module, the drains of the three tubes of the lower arm are at the same point, and this point is connected to the system ground through a small current detection resistor, which can be directly used as the + 15V power supply of the system ground as the reference point The drive control is performed, but the drains of the three tubes of the upper arm are not in place. You need to pass an external circuit. When the tube of the lower arm is turned on, the + 15V drive power of the lower arm charges the external capacitor at the same time. , The voltage drop of + 15V is maintained at both ends of the capacitor, and its low potential end is just connected to the drain of the upper arm IGBT tube. Therefore, the bootstrap function of the upper arm IGBT tube gate voltage is higher than the drain, very Drive the upper arm tube well.

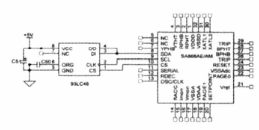

4. SA866AE / AM and EEPROM parameter setting

The serial three-wire interface of SA866AE / AM can be connected with 256-bit or 1024-bit serial EEPROM, such as 93C06 or 93C46. All parameters are stored in EEPROM, and are automatically downloaded through the serial interface after reset. This system intends to use 93LC46 for parameter storage and interface with SA866AE / AM.

If you want to know more, our website has product specifications for converter and inverter, you can go to ALLICDATA ELECTRONICS LIMITED to get more information