What are the current selection and usage methods of lithium battery protection board?

Lithium battery protection board current selection

1. The current of the lithium battery protection board is determined by the detection voltage of the protection IC and the internal resistance of the MOS tube. If the protection IC cannot be changed, you can change the MOS tube, such as DW01 and 8205MOS, use a MOS tube is 2 ~ 5A, use two MOS The parallel current of the tube will double. Some large-capacity mobile power supplies now use 3 to 4 MOS tubes in parallel.

2. Protection board protection current = overcurrent detection voltage / internal resistance of MOS tube (because two MOS tubes are connected in series, the internal resistance of MOS tube must be multiplied by 2 when calculating)

3. The selection of protection plate for lithium battery should be based on the capacity of the battery. Generally, the battery below 2000mAh has no special requirements. The general protection plate can be selected. The protection current is 2 ~ 5A. The discharge current of the general battery is 1C, 2000mAh or more. The battery protection current is preferably above 3A. For power batteries, many do not have a protection board, but PTC is connected in series, and the power is automatically cut off when the temperature is too high.

How to use lithium battery protection board

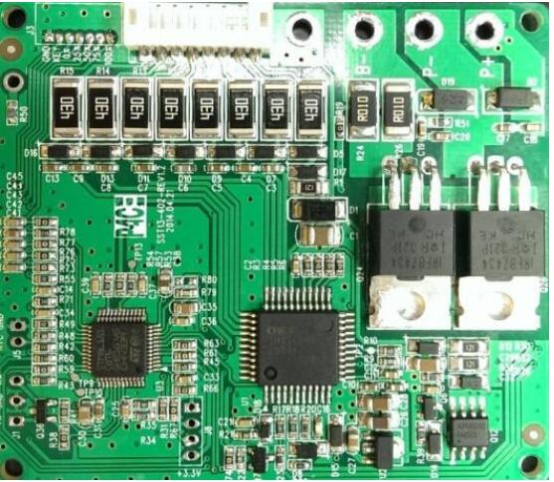

Lithium battery protection board has different circuits and parameters according to the use of IC, voltage, etc. The following is explained with DW01 equipped with MOS tube 8205A:

1. The normal working process of the lithium battery protection board is: when the cell voltage is between 2.5V and 4.3V, the first and third pins of DW01 output high level (equal to the power supply voltage), and the voltage of the second pin Is 0V. At this time, the voltages of pins 1 and 3 of DW01 will be added to pins 5 and 4 of 8205A. The two electronic switches in 8205A are in the conductive state because their G poles receive the voltage from DW01, that is, Both electronic switches are on. At this time, the negative electrode of the cell is directly connected to the P-end of the protection plate, and the protection plate has a voltage output.

2. Lithium battery protection board overcharge protection control principle: when the battery is normally charged by the charger, as the charging time increases, the voltage of the cell will become higher and higher, when the cell voltage rises to 4.4V, DW01 It will be considered that the cell voltage is already in the overcharge voltage state, and the output voltage of pin 3 is immediately turned off, so that the voltage of pin 3 becomes 0V, and the switch tube in 8205A is closed because there is no voltage on pin 4. At this time, the B- of the cell is disconnected from the P- of the protection board. That is, the charging circuit of the battery cell is cut off, and the battery cell will stop charging.

The protection board is in an overcharged state and has been kept. After the P and P- of the protection board are indirectly discharged, the overcharge control switch is closed, but the positive direction of the internal diode is the same as the direction of the discharge circuit, so the discharge circuit can discharge, when the voltage of the cell When it is lower than 4.3V, DW01 stops the overcharge protection state and outputs a high voltage on pin 3 again, so that the overcharge control tube in 8205A is turned on, that is, the B- of the cell and the protection board P- are reconnected. , The battery can be charged and discharged normally.

3. Protection board over-discharge protection control principle: When the battery cell is discharged through an external load, the voltage of the battery cell will slowly decrease, and at the same time, the voltage of the battery cell will be monitored in real time through the R1 resistor inside the DW01. When the battery cell voltage drops to about At 2.3V, DW01 will consider that the cell voltage is in the over-discharge voltage state, and immediately turn off the output voltage of pin 1, so that the voltage of pin 1 becomes 0V, and the switch tube in 8205A is closed because of no voltage at pin 5.

At this time, the B- of the cell is disconnected from the P- of the protection board. That is, the discharge circuit of the battery cell is cut off, and the battery cell will stop discharging. The protection board is in an over-discharge state and has been maintained. After P and P- of the protection board indirectly charge the voltage, DW01 will stop the over-discharge state immediately after detecting the charging voltage through B-, and output a high voltage on pin 1 again to turn on the over-discharge control tube in 8205A. That is, the B- of the battery cell and the P- of the protection board are reconnected, and the battery cell is directly charged by the charger.

4. Short-circuit protection control process: short-circuit protection is a limit form of over-current protection. Its control process and principle are the same as over-current protection. The short-circuit is only equivalent to adding a small resistance between PP- (about 0Ω) Make the load current of the protection board instantaneously reach above 10A, and the protection board will immediately perform over-current protection.

Lithium battery protection board, its role is to prevent the lithium battery from overcharging or over-discharging to play a corresponding protective role. A protective plate can protect the battery itself. If not, the lithium battery itself is easily damaged, and the second is a safety hazard. This is not a joke. Of course, the protection board is not used, because the internal resistance is small, the use time may be a little longer, and the price is cheaper, but personally think that safety is the first.

Lithium battery protection board purchase points

In order to protect the life of the lithium battery pack, it is recommended that the battery charging voltage should not exceed 3.6v at any time, that is, the protection voltage of the lithium battery protection board is not higher than 3.6v, the balanced voltage is recommended to be 3.4v-3.5v, and the battery discharge protection voltage is generally above 2.5v. can.

The maximum voltage of the charger is recommended to be 3.5 strings. The greater the self-discharge, the longer it takes to equalize. The cells with excessive self-discharge are difficult to equalize and need to be eliminated. Therefore, when choosing a lithium battery protection board, try to choose a 3.6v overvoltage protection and a balanced one starting around 3.5v.

In short, the lower the internal resistance of the lithium battery protection plate, the better, and the lower the heat. The current limit of the protection board is determined by the constantan wire sampling resistance, but the continuous current capability is determined by mos.

If you want to know more, our website has product specifications for lithium battery protection board, you can go to ALLICDATA ELECTRONICS LIMITED to get more information